Silicone Fiberglass Sleeving: Ensuring Safety and Reliability for Motor Insulation

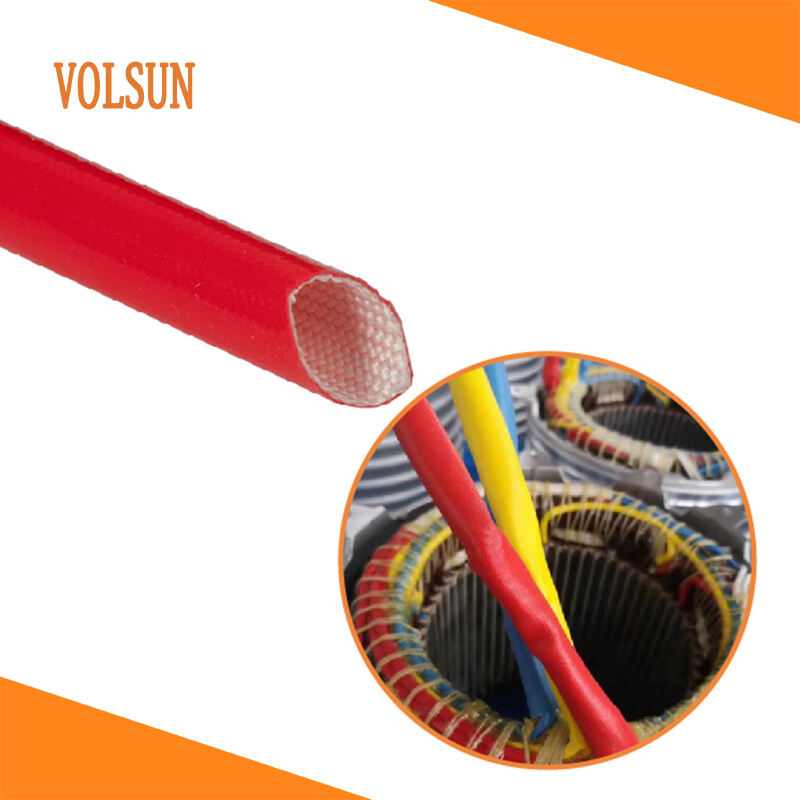

In an era where electric motors and electrical equipment increasingly demand high performance and reliability, quality insulating materials have become crucial to ensuring safe and stable operation. Silicone rubber fiberglass sleeving serves as a high-performance insulating sleeve widely used in critical areas such as motor lead wires, copper busbar connections, and wire harness protection, providing enterprises with a safe, durable, and flexible insulation solution.

Volsun produces silicone fiberglass sleeving in various voltage grades, including 1.5kV, 2.5kV, 4kV, and 7kV, meeting insulation requirements under different electrical environments. The product is made from high-quality silicone rubber combined with high-strength fiberglass, offering excellent electrical properties, mechanical strength, and temperature resistance. It can operate stably in extreme temperatures ranging from -40°C to +200°C, making it suitable for various demanding applications.

In addition to its outstanding temperature resistance, the fiberglass sleeve also exhibits excellent flame-retardant properties. Standard products meet the HB flame retardant rating, and custom-made V-0 grade high flame-retardant models are available, significantly enhancing equipment safety and effectively reducing fire risks.

In terms of production processes, we strictly adhere to a full process control system including compound mixing, fuzz removal, blank preparation, glue application, vulcanization, winding, and packaging. This ensures every meter of sleeving has uniform thickness, a dense coating, and strong adhesion. Particularly in the glue application stage, the number of coating passes is scientifically determined based on product diameter and voltage grade, ensuring a uniform and complete insulating layer.

Silicone fiberglass sleeving not only excels in performance but also comes in a complete range of specifications, packaged in 200m/roll, 100m/roll, and 50m/roll options to meet customer needs. Color choices include white, black, red, yellow, green, blue, pink, orange, and gray, facilitating wire identification.

Key performance indicators of the fiberglass sleeve are exceptional, with a tear strength of ≥50N/mm, strong adhesion, stable breakdown voltage, hydrolysis resistance, and flexibility, particularly maintaining good flexibility in low-temperature environments without easy cracking, ensuring a long service life.

Silicone fiberglass sleeving is widely used in various scenarios such as insulation for motor lead wire solder points, wire harness protection, and copper busbar wrapping. It is suitable for industries including new energy vehicles, industrial motors, household appliances, and rail transportation, making it an ideal choice for enhancing equipment insulation grades and safety performance.

We always prioritize quality, implementing full-process quality control from raw material selection to finished product delivery. This effectively avoids common quality issues such as “oil sand, stains, glue accumulation, insufficient glue,” ensuring every roll of product delivered meets customer expectations.

If you are looking for reliable, well-specified, and high-quality silicone fiberglass sleeving supplier, please feel free to contact us, we are committed to providing tailored insulation solutions for you.