Why does the photovoltaic industry need to use cold shrink tubing?

With the growing global demand for renewable energy, photovoltaic power generation, as a clean and sustainable form of energy, is being used more and more widely. However, photovoltaic power stations are exposed to outdoor environments for a long time and face various harsh tests, including but not limited to the following:

Ultraviolet radiation: Long-term exposure to sunlight will accelerate the aging of materials, causing cracking and embrittlement of connector sheaths, and ultimately affect their insulation performance and mechanical strength.

Moisture and rain: Water vapor and rain will penetrate into the connector, causing short circuits, leakage and other faults, seriously affecting the safety and reliability of photovoltaic systems.

Salt spray corrosion: For photovoltaic projects at sea or in coastal areas, salt spray corrosion is an issue that cannot be ignored. Chloride ions in salt spray will accelerate the corrosion of metal materials and cause connector failure.

So are there any products or solutions that can provide reliable protection for photovoltaic junction box connectors? After continuous exploration and experimentation, people have found that the use of cold shrink tubing can solve the above problems. Why?

Excellent UV resistance: Cold shrink tubing can effectively resist sunlight radiation, delay material aging, and can be used stably outdoors for a long time.

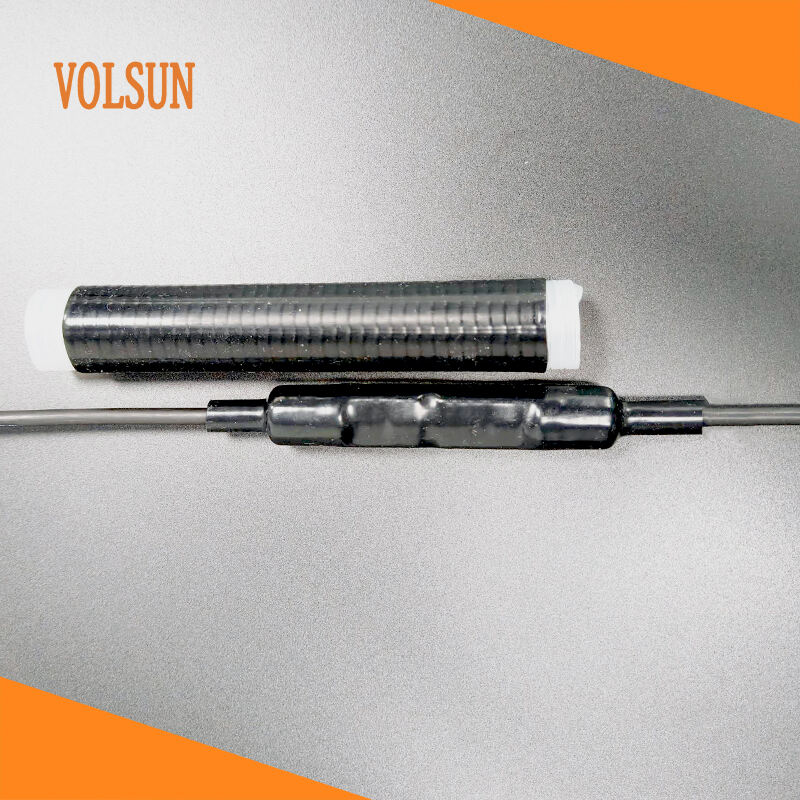

Excellent sealing and waterproof performance: After shrinking, the cold shrink tube can fit the connector tightly, achieve IP68 level waterproof sealing, effectively prevent water vapor and rainwater from penetrating, and ensure the safe and reliable operation of the connector.

Excellent acid and alkali salt spray corrosion resistance: The cold shrink tube is made of high-quality rubber raw materials and can effectively resist the corrosion of salt spray, acid and alkali and other chemical substances. Volsun, a cold shrink tube manufacturer, has conducted salt spray corrosion resistance tests to prove this excellent performance.

Cold shrink tubes have been successfully used in many photovoltaic projects. In offshore photovoltaic power stations in coastal areas, Volsun cold shrink tubes are successfully used for waterproof and moisture-proof protection of M4C connectors in offshore photovoltaic projects. With its excellent salt spray corrosion resistance and waterproof sealing performance, it effectively protects the junction box connector from erosion in harsh environments.

In large-scale ground photovoltaic power stations in the northwest region, Volsun cold shrink tubes have excellent anti-ultraviolet aging performance, ensuring the stable operation of the junction box connector in high temperature and strong ultraviolet environments.

In short, Volsun cold shrink tubing has become an ideal choice for the protection of junction box connectors in the photovoltaic industry with its excellent resistance to UV rays, high temperature, acid, alkali and salt spray corrosion, IP68 waterproof sealing grade and excellent insulation performance.