Volsun Shaft Grounding Ring Technology Products & Bearing Protection Motors From Bearing Damage

Description

Volsun’s Shaft Grounding Ring Technology products provide a simple, reliable way to protect motors and bearings from damaging electrical currents. Designed for easy installation and long-term performance, Volsun grounding rings divert stray shaft currents safely to ground, preventing the electrical pitting and fluting that cause premature bearing failure. These compact devices fit a wide range of motor sizes and types, offering a versatile solution for industrial, commercial, and renewable energy applications.

At the heart of Volsun technology is a conductive ring paired with high-quality carbon brushes that maintain continuous contact with the rotating shaft. As unwanted current travels along the shaft, the brushes capture it and feed it into the grounding ring, which routes the current to a grounded point. This controlled path prevents currents from passing through bearing surfaces, eliminating the micro-arcing that erodes bearing races and rollers. The result is extended bearing life, reduced maintenance costs, and increased equipment uptime.

Volsun’s grounding rings are built from durable materials that withstand harsh environments. The rings and brush assemblies resist corrosion and wear, maintaining consistent performance under vibration, temperature swings, and dust. Installation is straightforward: the ring mounts to the motor housing, brushes are sized and positioned for optimal contact, and a grounding lead connects the assembly to earth. Many models are available with adjustable brush pressure and replaceable brush cartridges, letting maintenance teams perform quick service without removing the motor from service.

Volsun products support a wide spectrum of motors and drives, including variable frequency drives (VFDs) known to generate shaft currents. By intercepting circulating currents, Volsun grounding rings protect not only bearings but also surrounding equipment and sensors that can be affected by stray voltage. For facilities running critical processes, Volsun systems offer a proactive protection measure that lowers the risk of sudden failures and unplanned downtime.

Maintenance-friendly design reduces lifecycle costs. The replaceable brushes and modular components make routine checks fast and cost-effective. Technical support and clear installation guides help technicians choose the right model and size for each application, ensuring optimal performance from day one. Volsun’s grounding rings are also compact, allowing use in tight spaces where larger grounding solutions are impractical.

Choose Volsun’s Shaft Grounding Ring Technology to safeguard motors and bearings against electrical damage. With reliable current diversion, robust construction, and easy maintenance, Volsun products deliver peace of mind and measurable savings through longer bearing life, fewer repairs, and improved operational reliability

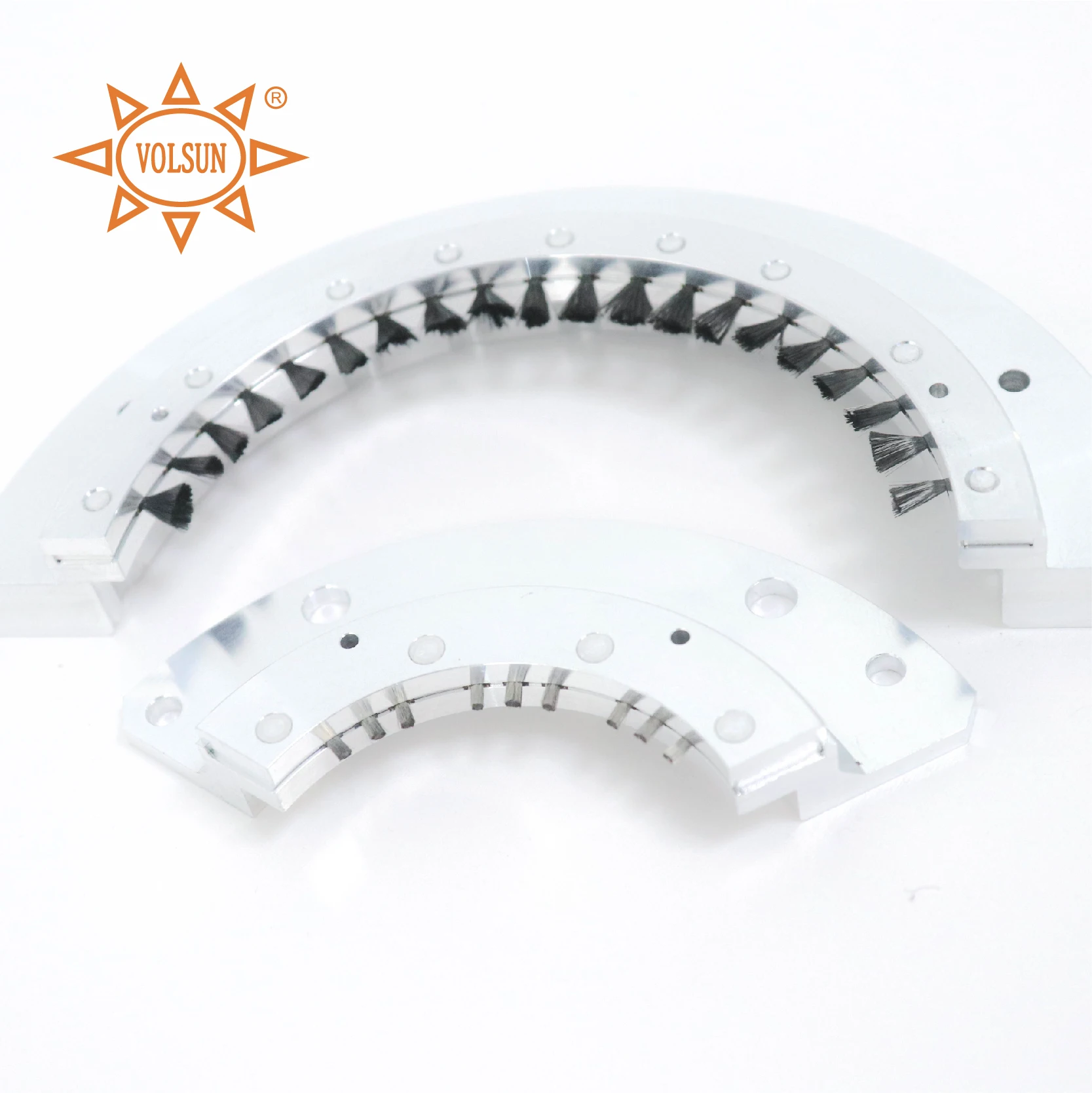

Volsun VS-RD Series Shaft Grounding Rings

VS-RD series conductive rings solve the problem of motor shaft electro-corrosion by bypass grounding. It is composed of conductive fibers, metal bodies, etc., and is used for electro-corrosion protection of variable frequency motors and their coupled equipment. VS-RD series conductive rings can reduce the induced potential between the bearing and the grounded housing, effectively reduce the damages of electro-corrosion caused by shaft current, protect motor bearings to ensure long-term and stable operation of the motor

Item |

Test Data |

Test Standard |

Static resistance |

<1Ω |

/ |

Dynamic resistance |

≤10Ω |

/ |

Fiber pull-off force |

≥100·30s |

/ |

Salt spray test |

No damage to fibers |

/ |

Durability test - Water cooling/Oil cooling |

<0.5mm/30Wkm

<0.2mm/30Wkm

|

/ |

High temperature test |

See enterprise standards |

/ |

Low temperature test |

See enterprise standards |

/ |

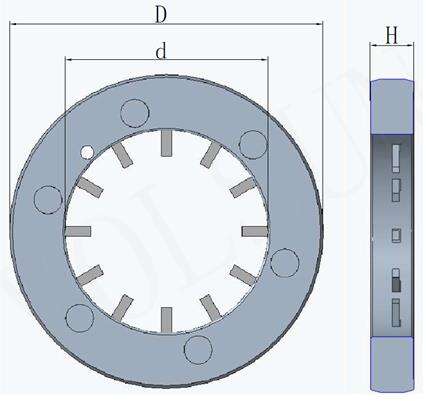

Dimensions

OD - mm |

Matching Shaft Diameter - mm |

Height - mm |

30 |

10 |

≥7 |

35 |

17 |

≥7 |

38 |

13 |

≥7 |

40 |

18 |

≥7 |

47 |

25 |

≥7 |

50 |

25 |

≥7 |

52 |

26 |

≥7 |

58 |

39 |

≥7 |

60 |

40 |

≥7 |

62 |

36 |

≥7 |

66 |

41.5 |

≥7 |

70 |

40 |

≥7 |

72 |

43 |

≥7.5 |

78 |

54 |

≥7.5 |

85 |

59 |

≥7.5 |

92 |

70 |

≥7.5 |

108 |

80 |

≥7.5 |

128 |

79.5 |

≥7.5 |

Note:The other sizes and packing are available as request

Packing & Delivery

Suzhou Volsun Electronics Technology Co., Ltd. was founded in 2006. We keep focusing on the R&D, production and sales in insulation, sealing & protection solutions for over 19 years

Quality is our culture. Volsun has a modern quality management system, which has passed a series of quality system certification such as IATF16949, ISO9001 etc

FAQ

A: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product orders

A: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packaging

A: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your products

A: It depends on the model, we produce more than 1500 tons of rubber materials per month

Q 5. What kind of certificates do you have

A1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk order

A1: We provide pre-production samples to all customers before mass production if needed

A2: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 7: Can you provide customized service

A: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements