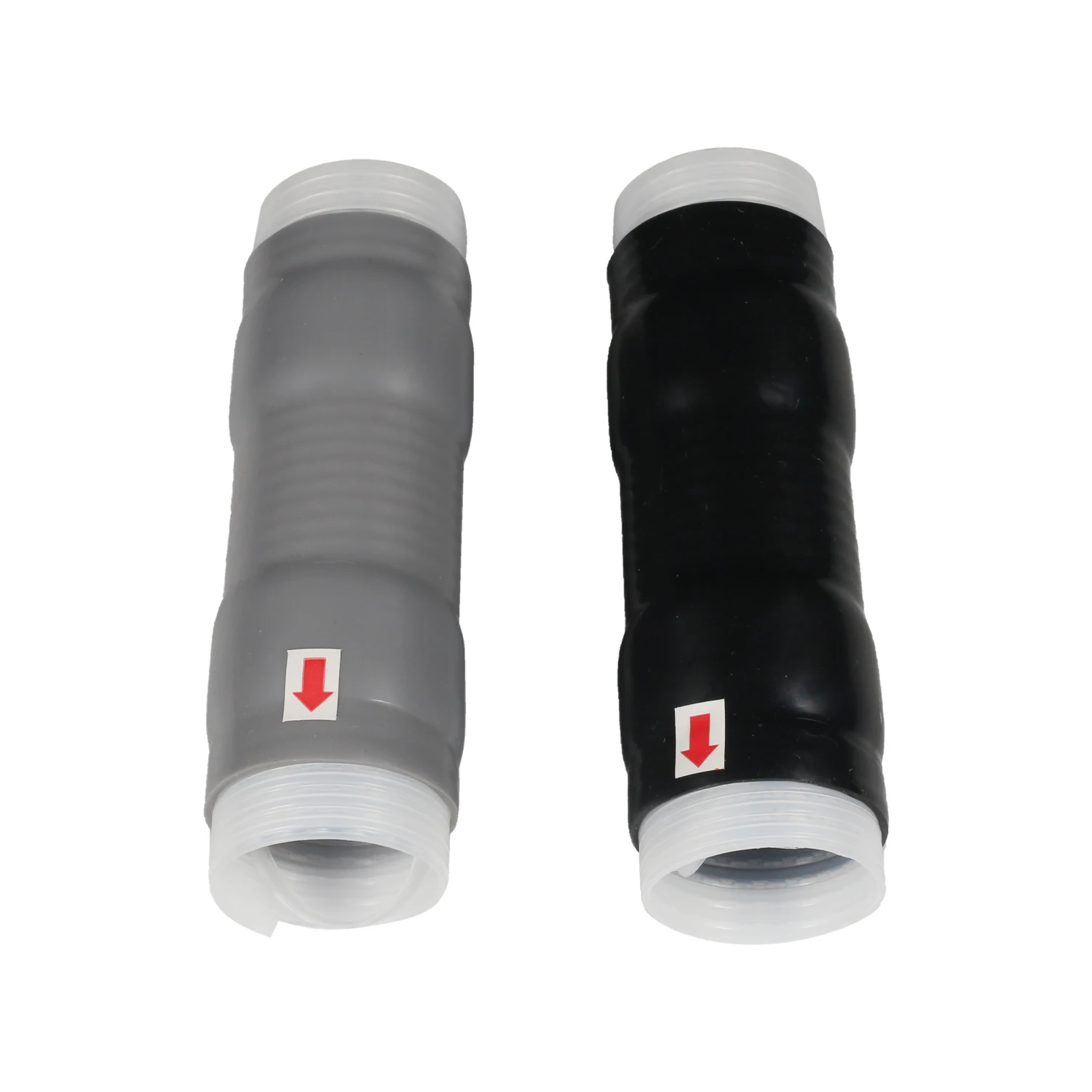

UV Resistant Silicone Built in Mastic Cold Shrink Tube Accessories for Telecom Base Station Site

Description

Introducing, the Volsun’s UV Resistant Silicone Built in Mastic Cold Shrink Tube Accessories for Telecom Base Station Site. This innovative product is designed to provide long-lasting protection and reliability for telecom equipment in outdoor environments.

Made with high-quality silicone material, the Volsun’s Cold Shrink Tube Accessories offer excellent UV resistance to ensure durability and performance in extreme weather conditions. The built-in mastic provides a tight seal that is water-resistant, helping to prevent moisture and dust from penetrating the connection points.

Installation is quick and easy with the cold shrink technology, eliminating the need for heat guns or other tools. Simply slide the tube over the connection, remove the plastic core, and the tube shrinks to fit snugly in place. The built-in mastic molds around the connection point, creating a secure seal that protects against corrosion and mechanical damage.

Ideal for use in telecom base station sites, these accessories provide added security and stability for critical equipment. With their UV resistance, they can withstand prolonged exposure to sunlight without degrading or losing their protective properties. This makes them perfect for outdoor installations where equipment is subjected to harsh environmental conditions.

The Volsun’s Cold Shrink Tube Accessories are designed to meet the high standards of telecom industry professionals. They are rigorously tested to ensure reliability and performance, so you can trust that your equipment is well-protected. Plus, the silicone material is non-toxic and safe for the environment, making it a responsible choice for your telecom infrastructure.

Invest in the Volsun’s UV Resistant Silicone Built in Mastic Cold Shrink Tube Accessories for Telecom Base Station Site and enjoy peace of mind knowing your equipment is secure. With their durable construction and easy installation, these accessories are a smart investment for any telecom installation project. Trust Volsun to provide quality products that stand the test of time

Cable accessories RFS cable cold shrink tube IP68

2. Waterproof and Sealing Class: IP68

3. Shrink Ratio :5:1

4. Good weather resistance, ozone ageing, ultraviolet and salt mist corrosion resistance

5. Simple installation

6. Standard color:Black, white, grey, etc

Properties |

Typical Data |

Test Method |

Shore Hardness |

40±5A |

GB/T 531-2008 |

Tensile Strength |

≥9.0MPa |

GB/T 528-2009 |

100% Stress at Definite Elongation |

≤1.2MPa |

GB/T 528-2009 |

200% Stress at Definite Elongation |

≤2.0MPa |

GB/T 528-2009 |

Elongation at Break |

>800% |

GB/T 528-2009 |

Tear Strength |

≥35kN/m |

GB/T 529-2008 |

Size |

Inner Diameter - mm |

Min Cable Outer Diameter - mm |

Max Cable Outer Diameter - mm |

Full Recovered Length - mm |

VS15-2 |

15 |

5 |

13 |

50 |

VS28-6 |

28 |

7.0 |

25.0 |

150 |

VS40-5.5 |

40 |

11.0 |

33.0 |

140 |

VS45-7 |

45 |

13.5 |

39.0 |

178 |

VS60-9 |

60 |

20.5 |

51.0 |

230 |

VS70-8 |

70 |

25.0 |

63.0 |

203 |

Trade terms |

FOB, EXW, CIF, DDU, DDP, CFR |

Payment terms |

T/T, L/C, Negotiable |

Supply capability |

1,000,000 pieces per month |

Lead time |

Usually 2-3 working days |

Shipment |

Express, Air, Sea |

Port |

Shanghai, Ningbo, Shenzhen |

Sample availability |

Yes |

Sample time |

Usually 1-2 days |

Packaging |

Normal: Plastic bag & Carton & Pallet Special: Customized packing |

A: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product orders

A: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packaging

A: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your products

A: It depends on the model, we produce more than 1500 tons of rubber materials per month

Q 5. What kind of certificates do you have

A1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk order

A1: We provide pre-production samples to all customers before mass production if needed

A3: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 9: Can you provide customized service

A: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements.