Shaft Voltage Mitigation Device Shaft Grounding Ring for Industrial Motors New Energy Vehicles Marine Applications

Description

Volsun’s Shaft Voltage Mitigation Device — Shaft Grounding Ring for Industrial Motors, New Energy Vehicles, and Marine Applications.

The Volsun Shaft Voltage Mitigation Device is a simple, reliable solution designed to protect motors, bearings, and electrical systems from shaft voltage and stray currents. Built for heavy-duty industrial motors, new energy vehicles, and marine equipment, this shaft grounding ring helps extend motor life, reduce maintenance, and avoid costly downtime.

This device uses a flexible conductive ring that sits around the motor shaft. As the motor runs, any unwanted voltage on the shaft is safely carried away through the ring to an earth connection. That prevents electrical discharge across the bearing surfaces, which is a common cause of bearing damage, noise, and vibration. The Volsun ring is made from durable conductive materials and fine fibers that give a low-resistance path while still allowing smooth shaft rotation.

Installation is straightforward. The Volsun ring mounts easily on the motor housing or shaft support with simple hardware. It fits a wide range of shaft sizes and can be adjusted or replaced quickly during routine service. The ring works with both new and existing motors, making it ideal for upgrades or retrofits. Clear mounting options and a sturdy grounding lead let technicians connect the device to the equipment ground with confidence.

Volsun designed this device with tough environments in mind. It resists corrosion, dust, and moisture, so it performs well in factories, ships, and vehicle systems. For new energy vehicles like electric buses and delivery trucks, the ring protects traction motors and generators from inverter-induced shaft voltages. In marine applications, where salt, moisture, and long duty cycles add stress, the Volsun ring helps prevent early bearing failure and maintains reliable operation.

Performance benefits include reduced bearing current damage, lower vibration and noise, extended bearing life, and fewer unplanned repairs. The device also supports higher power operation by giving a safe path for stray currents that could otherwise find destructive routes. This means quieter, smoother machines and more predictable maintenance schedules.

Volsun offers the shaft grounding ring in several sizes and configurations to suit common motor frames and vehicle drivetrains. Each unit undergoes quality checks to ensure consistent conductivity and long-term performance. For engineers and maintenance teams looking to protect assets and reduce lifecycle costs, the Volsun Shaft Voltage Mitigation Device is a practical, cost-effective choice that delivers reliable protection across industrial motors, new energy vehicles, and marine systems

Volsun VS-RD Series Shaft Grounding Rings

VS-RD series shaft grounding rings are composed of conductive fibers and metal bodies and are used for electric corrosion protection of variable frequency motors and their coupling equipment. VS-RD series conductive rings can reduce the potential induction between the bearing and the grounded chassis, effectively solve the phenomenon of electrical corrosion caused by shaft current, and protect the bearing from damage

Item |

Test Data |

Test Standard |

Static resistance |

<1Ω |

/ |

Dynamic resistance |

≤10Ω |

/ |

Fiber pull-off force |

≥100·30s |

/ |

Salt spray test |

No fiber damage |

/ |

Durability test |

A3 |

/ |

High temperature test |

≥120h |

/ |

Low temperature test |

≥15times |

/ |

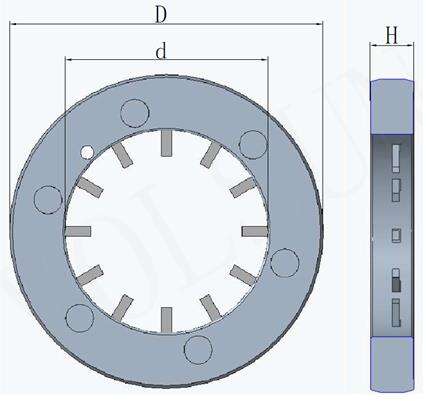

Dimensions

OD - mm |

ID - mm |

Height - mm |

Applicable shaft diameter - mm |

30 |

15 |

7 |

10 |

38 |

19 |

7 |

13 |

38 |

22 |

7 |

18 |

40 |

24 |

7 |

18 |

47 |

31 |

7 |

25 |

49 |

32 |

7 |

26 |

50 |

30 |

7 |

24 |

50 |

31 |

7 |

25 |

53 |

30 |

7 |

25 |

53 |

36 |

7 |

30 |

55 |

39 |

7 |

35 |

57 |

36 |

7 |

30 |

60 |

44 |

7 |

38 |

62 |

41 |

7 |

35 |

70 |

46 |

7 |

40 |

72 |

49 |

7 |

43 |

75 |

58 |

7 |

52 |

78 |

58 |

7 |

52 |

Note:Special size and packing are available as request

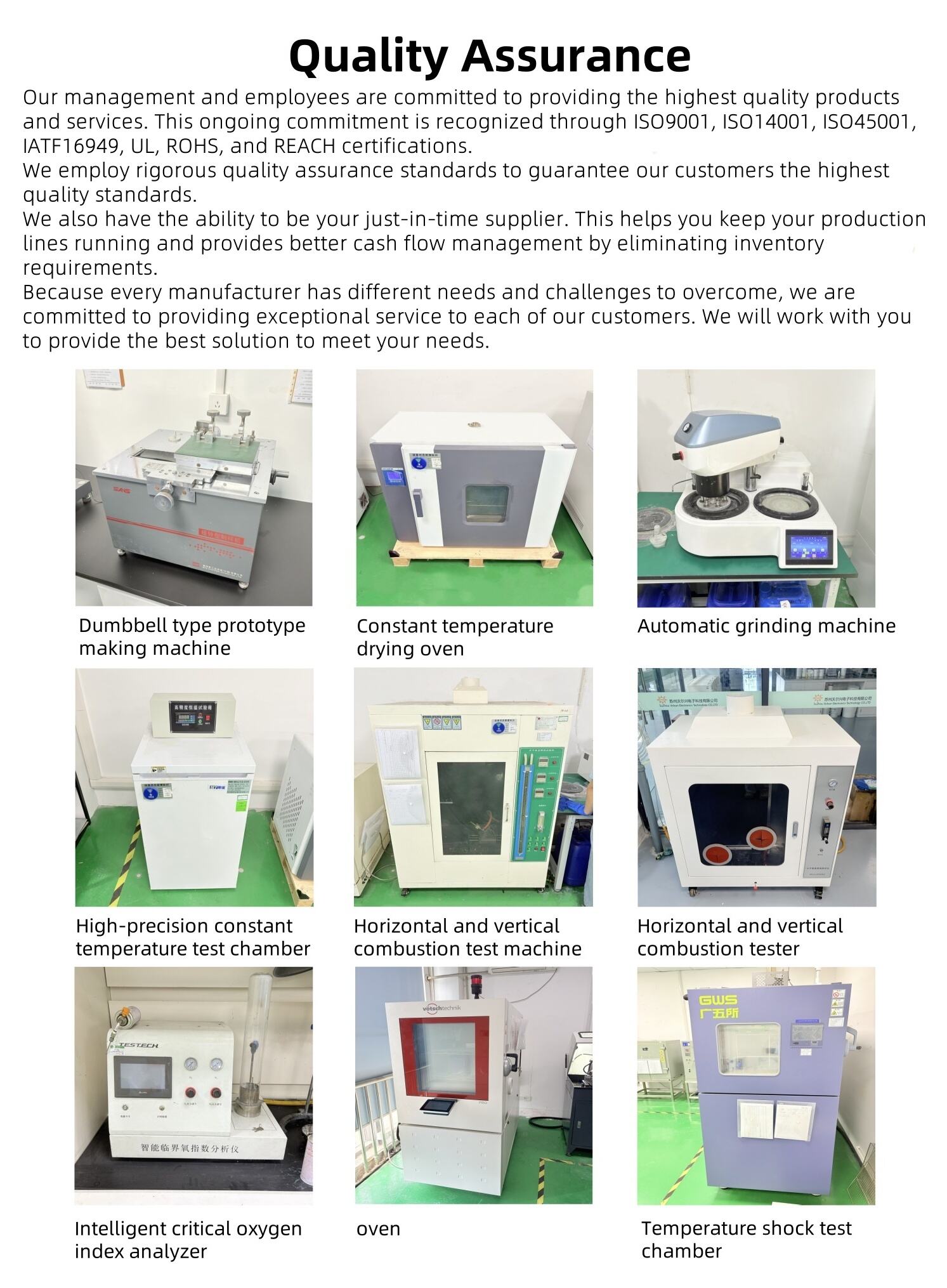

Suzhou Volsun Electronics Technology Co., Ltd. was founded in 2006. We keep focusing on the R&D, production and sales in insulation, sealing & protection solutions

Volsun has a modern quality management system, which has passed a series of quality system certification such as IATF16949, ISO9001 etc

FAQ

A: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product orders

A: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packaging

A: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your products

A: It depends on the model, we produce more than 1500 tons of rubber materials per month

Q 5. What kind of certificates do you have

A1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk order

A1: We provide pre-production samples to all customers before mass production if needed

A2: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 7: Can you provide customized service

A: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements