Shaft Grounding Ring for Protect the Motor Bearings From Shaft Voltage and Electrical Damage

Description

Volsun's Shaft Grounding Ring is a must-have solution for protecting your motor bearings from shaft voltage and electrical damage. This innovative product is designed to effectively dissipate harmful currents that can build up on the shaft of your motor, preventing them from causing potential damage to the bearings.

Made with high-quality materials, Volsun's Shaft Grounding Ring is durable and reliable, ensuring long-lasting protection for your motor. It is easy to install and compatible with a wide range of motors, making it a versatile solution for various applications.

By using Volsun's Shaft Grounding Ring, you can rest assured that your motor bearings are safe from the effects of shaft voltage and electrical damage. This proactive approach to maintenance can help extend the lifespan of your motor and prevent costly downtime caused by unexpected failures.

Protect your investment and keep your operations running smoothly with Volsun's Shaft Grounding Ring. Don't wait until it's too late – invest in this essential product today and enjoy peace of mind knowing that your motor is well-protected.

Trust Volsun for all your motor protection needs. With a reputation for excellence and a commitment to customer satisfaction, Volsun is the brand you can rely on for high-quality products that deliver reliable performance.

Don't take chances when it comes to protecting your motor bearings. Invest in Volsun's Shaft Grounding Ring and safeguard your equipment against the damaging effects of shaft voltage and electrical currents. Order yours today and experience the peace of mind that comes with knowing your motor is safe and secure

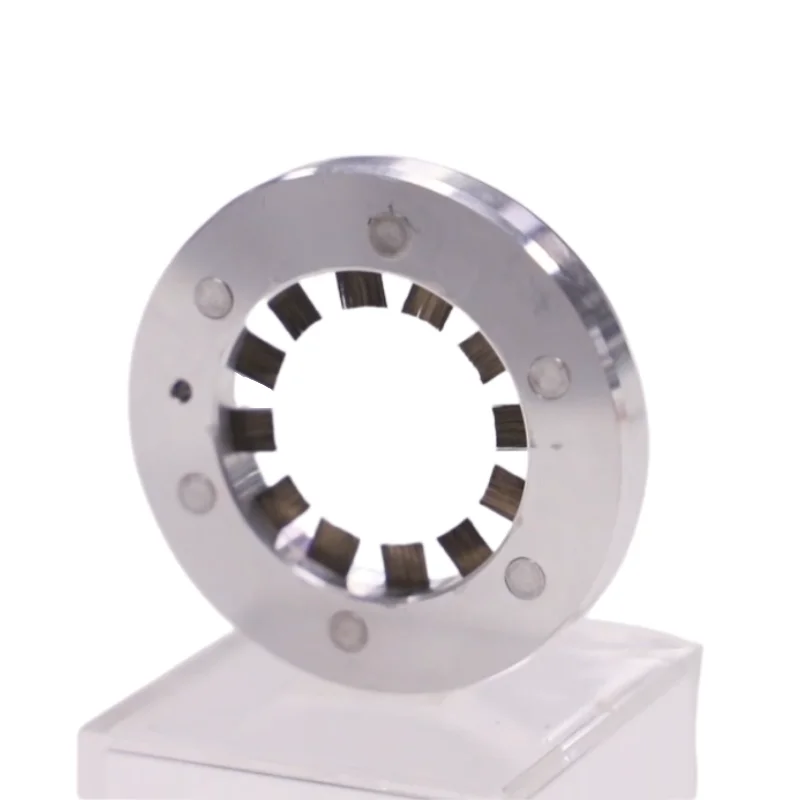

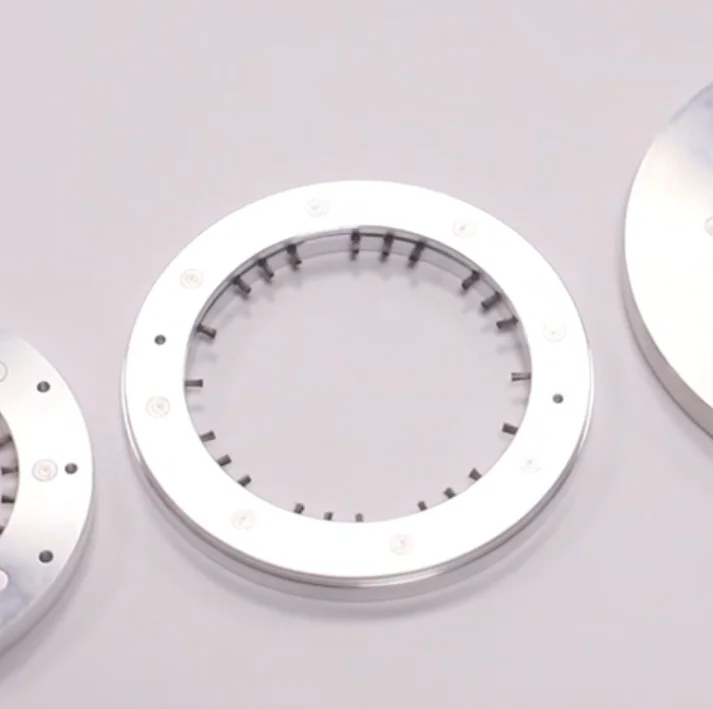

Volsun VS-RD Series Shaft Grounding Rings

VS-RD series conductive rings solve the problem of motor shaft electro-corrosion by bypass grounding. It is composed of conductive fibers, metal bodies, etc., and is used for electro-corrosion protection of variable frequency motors and their coupled equipment. VS-RD series conductive rings can reduce the induced potential between the bearing and the grounded housing, effectively reduce the damages of electro-corrosion caused by shaft current, protect motor bearings to ensure long-term and stable operation of the motor

Item |

Test Data |

Test Standard |

Static resistance |

<1Ω |

/ |

Dynamic resistance |

≤10Ω |

/ |

Fiber pull-off force |

≥100·30s |

/ |

Salt spray test |

No damage to fibers |

/ |

Durability test - Water cooling/Oil cooling |

<0.5mm/30Wkm

<0.2mm/30Wkm

|

/ |

High temperature test |

See enterprise standards |

/ |

Low temperature test |

See enterprise standards |

/ |

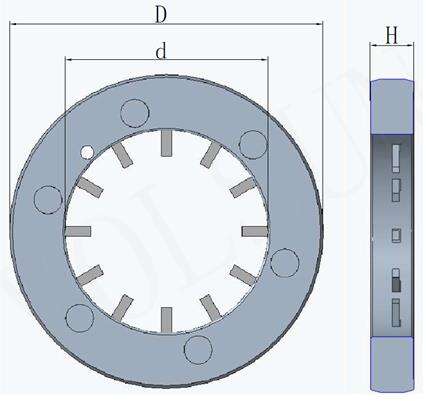

Dimensions

O. D - mm |

Matching Shaft Diameter - mm |

Height - mm |

30 |

10 |

≥7 |

35 |

17 |

≥7 |

38 |

13 |

≥7 |

40 |

18 |

≥7 |

47 |

25 |

≥7 |

50 |

25 |

≥7 |

52 |

26 |

≥7 |

58 |

39 |

≥7 |

60 |

40 |

≥7 |

62 |

36 |

≥7 |

66 |

41.5 |

≥7 |

70 |

40 |

≥7 |

72 |

43 |

≥7.5 |

78 |

54 |

≥7.5 |

85 |

59 |

≥7.5 |

92 |

70 |

≥7.5 |

108 |

80 |

≥7.5 |

128 |

79.5 |

≥7.5 |

Note:The other sizes and packing are available as request

Packing & Delivery

FAQ

A: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product orders

A: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packaging

A: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your products

A: It depends on the model, we produce more than 1500 tons of rubber materials per month

Q 5. What kind of certificates do you have

A1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk order

A1: We provide pre-production samples to all customers before mass production if needed

A3: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 7: Can you provide customized service

A: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes