Shaft Grounding Ring for New Energy Vehicle Motors with Alloy Material Flexible Structure Excellent Conductive Properties

Description

The Volsun Shaft Grounding Ring is a high-quality product designed specifically for new energy vehicle motors. Made from a carefully selected alloy material, this grounding ring offers excellent conductive properties that help improve the overall performance and longevity of electric motors. It is an essential component for protecting motors from electrical damage by effectively grounding shaft currents that can otherwise cause wear and tear.

One of the standout features of the Volsun Shaft Grounding Ring is its flexible structure. Unlike traditional rigid grounding rings, this flexible design allows it to adapt easily to different shaft sizes and shapes. This flexibility ensures a snug fit on the motor shaft, which improves contact and boosts the efficiency of grounding electrical currents. Because it fits well, it helps reduce the risk of motor failures caused by shaft currents, making it a reliable choice for new energy vehicles.

The alloy material used in this grounding ring is chosen for its strength and conductivity. Alloy metals provide the perfect balance between durability and electrical performance. The Volsun grounding ring is built to last, resisting corrosion and wear even in demanding conditions. This durability means that it maintains excellent electrical contact over time, which is critical for maintaining the health of motor components.

Installation is straightforward due to the product’s flexible design and high-quality construction. The grounding ring can be easily mounted on the motor shaft without requiring complex tools or adjustments. This makes it a practical choice for vehicle manufacturers and maintenance teams who want a reliable and cost-effective solution for reducing motor shaft currents.

By using the Volsun Shaft Grounding Ring in new energy vehicle motors, users can expect improved motor reliability and longer service life. It helps protect against electrical damage, which can otherwise lead to costly repairs or motor replacements. Additionally, this grounding ring contributes to the smooth operation of electric motors by providing a stable electrical path to ground, reducing electrical noise and interference.

The Volsun Shaft Grounding Ring combines a flexible structure with robust alloy material to deliver excellent conductive properties. It is designed to meet the unique needs of new energy vehicle motors, providing effective protection against shaft currents. Whether for manufacturing or maintenance, Volsun offers a dependable, easy-to-install solution that helps keep electric motors running safely and efficiently

Volsun VS-RD Series Shaft Grounding Rings

VS-RD series shaft grounding rings are composed of conductive fibers and metal bodies and are used for electric corrosion protection of variable frequency motors and their coupling equipment. VS-RD series conductive rings can reduce the potential induction between the bearing and the grounded chassis, effectively solve the phenomenon of electrical corrosion caused by shaft current, and protect the bearing from damage

Item |

Test Data |

Test Standard |

Static resistance |

<1Ω |

/ |

Dynamic resistance |

≤10Ω |

/ |

Fiber pull-off force |

≥100·30s |

/ |

Salt spray test |

No fiber damage |

/ |

Durability test |

A3 |

/ |

High temperature test |

≥120h |

/ |

Low temperature test |

≥15times |

/ |

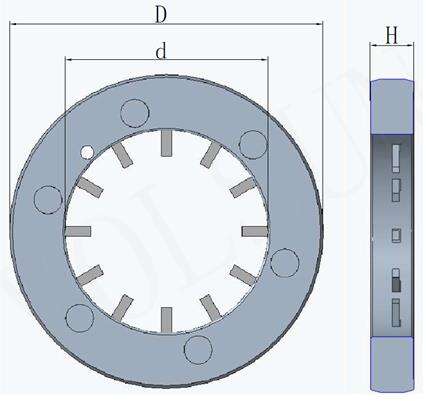

Dimensions

OD - mm |

ID - mm |

Height - mm |

Applicable shaft diameter - mm |

30 |

15 |

7 |

10 |

38 |

19 |

7 |

13 |

38 |

22 |

7 |

18 |

40 |

24 |

7 |

18 |

47 |

31 |

7 |

25 |

49 |

32 |

7 |

26 |

50 |

30 |

7 |

24 |

50 |

31 |

7 |

25 |

53 |

30 |

7 |

25 |

53 |

36 |

7 |

30 |

55 |

39 |

7 |

35 |

57 |

36 |

7 |

30 |

60 |

44 |

7 |

38 |

62 |

41 |

7 |

35 |

70 |

46 |

7 |

40 |

72 |

49 |

7 |

43 |

75 |

58 |

7 |

52 |

78 |

58 |

7 |

52 |

Note:Special size and packing are available as request

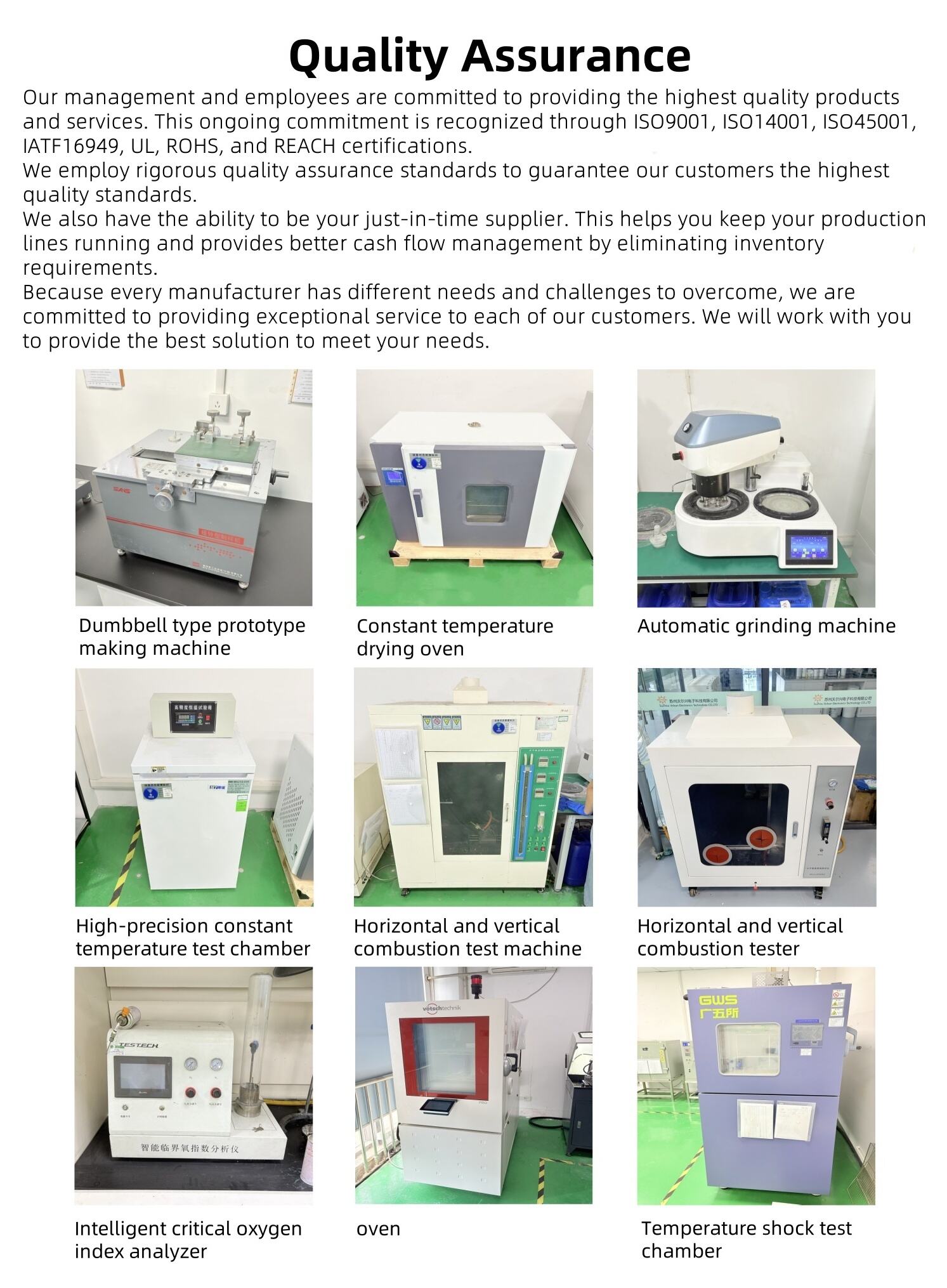

Suzhou Volsun Electronics Technology Co., Ltd. was founded in 2006. We keep focusing on the R&D, production and sales in insulation, sealing & protection solutions

Volsun has a modern quality management system, which has passed a series of quality system certification such as IATF16949, ISO9001 etc

FAQ

A: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product orders

A: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packaging

A: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your products

A: It depends on the model, we produce more than 1500 tons of rubber materials per month

Q 5. What kind of certificates do you have

A1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk order

A1: We provide pre-production samples to all customers before mass production if needed

A3: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 7: Can you provide customized service

A: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements.