SBRS Dual Wall Heat Shrink Thermofit Adhesive Cable Sleeve PE Material for Low Voltage Applications

Description

The Volsun SBRS Dual Wall Heat Shrink Thermofit Adhesive Cable Sleeve is a reliable and easy-to-use solution designed to protect and insulate low voltage cables. Made from high-quality PE (polyethylene) material, this cable sleeve is perfect for a variety of electrical and electronic applications. Whether you are working on home wiring, automotive repairs, or small electronic projects, this heat shrink sleeve offers great protection and durability

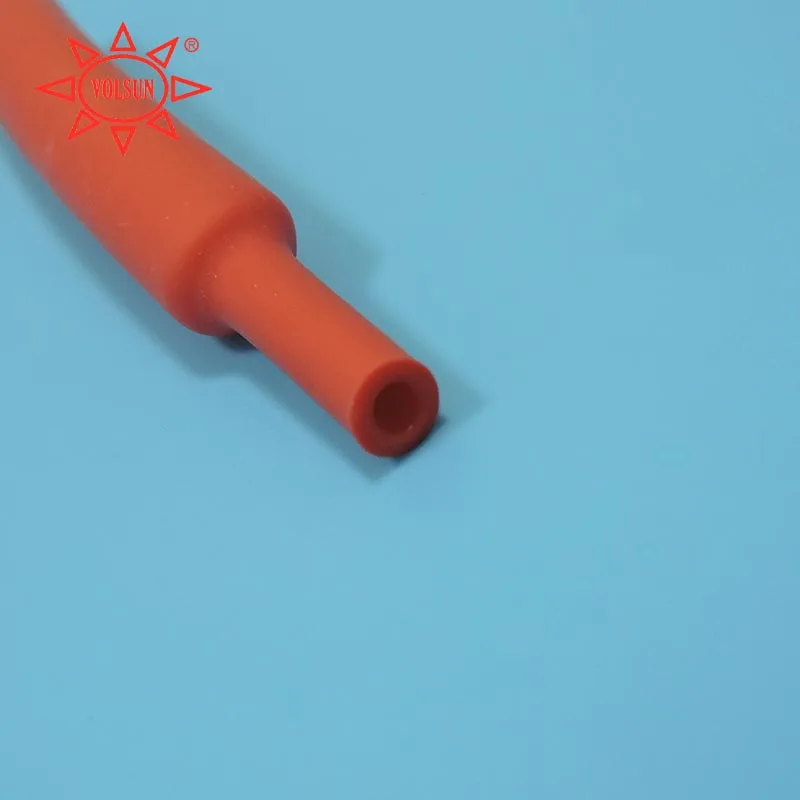

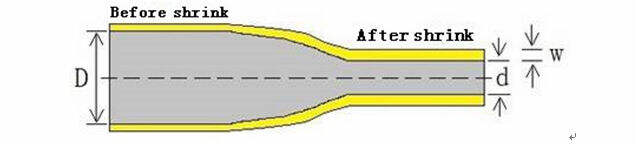

One of the main features of the Volsun SBRS cable sleeve is its dual wall design. This means it has an outer layer that shrinks tightly when heated and an inner adhesive layer that melts and bonds to the cable surface. When you apply heat, the sleeve shrinks and the adhesive fills any gaps, creating a solid seal. This not only offers excellent insulation but also prevents moisture, dust, and other contaminants from reaching the cables. As a result, your cables stay safe and last longer

The material used in this product is polyethylene, known for being flexible yet tough. It resists wear and tear, making it suitable for everyday usage. The Volsun cable sleeve also withstands low voltages easily, which makes it a good choice for household electronics, automotive circuits, and other low voltage wiring tasks. It can handle temperature changes and small impacts without cracking or breaking

Using the SBRS Dual Wall Heat Shrink Sleeve is simple. Cut the sleeve to the desired length, slide it over the cable or wire, and then apply heat using a heat gun, lighter, or hair dryer. The sleeve quickly shrinks to fit snugly around the cable, creating a professional finish and strong protection. The adhesive inside will also bond securely, making sure the sleeve does not move or slip over time

The Volsun SBRS Dual Wall Heat Shrink Thermofit Adhesive Cable Sleeve is an excellent choice for anyone needing reliable insulation for low voltage cables. Its strong PE material, adhesive inner layer, and easy heat-shrink feature provide long-lasting protection from damage, moisture, and dirt. Ideal for DIY projects or professional use, this cable sleeve ensures your wiring stays safe and secure. With Volsun’s trusted quality, you get a durable and practical solution that helps keep your electrical connections neat and protected

SBRS-125G(2X)(3X)(4X) adhesive lined dual wall heat shrink Thermofit adhesive cable sleeve

Description

heat shrink Thermofit adhesive cable sleeve is a cross-linked polyolefin tube that is extruded with an inner layer of adhesive. The inner layer of adhesive, with superior sealing capability, is also a buffer against mechanical strain. heat shrink Thermofit adhesive cable sleeve is designed to provide superior sealing against water, corrosive gas and chemicals. Typical applications include environmental sealing of in-line splices, sealing and strain relief of connectors and terminals, abrasion protection and electrical insulation of automotive wiring harness splices and valuable components, fleet & marine sealing & protection and wire bundling etc

Features

² Standard:UL 224

² Shrink ratio:2:1,3:1,4:1,6:1

² Flame retardant out layer, environmentally friendly, UV resistant

² Shrink temperature:70°C~125°C

² Continuous operating temperature:-45°C~125°C

² RoHS compliant

² Standard colors:black, other colors are available on request

Technical Data

Property |

Typical data |

Test method/condition |

Tensile strength |

≥10.4MPa |

ASTM D 2671 |

Elongation at break |

≥300% |

ASTM D 2671 |

Tensile strength after heat aging |

≥7.3MPa |

158°C×168h |

Elongation after heat aging |

≥100% |

158°C×168h |

Longitudinal change |

-8%~+8% |

ASTM D 2671 |

Flammability |

Self extinguishing in 30 sec |

AMS-DTL-23053/4 |

Voltage withstand Rated voltage 600V |

2500V,1min no breakdown |

UL 224 |

Heat shock |

No cracks, no dripping |

UL 224,250°C×4h |

Dielectric strength |

≥15kv/mm |

IEC 60243 |

Volume resistivity |

≥1014Ω. cm |

IEC 60093 |

Property |

Typical data |

Test method/condition |

Softening point |

95±5°C |

ASTM E 28 |

Water absorption |

<<>0.5% |

ASTM D 570 |

Peel strength PE |

≥120N/25mm |

ASTM D 1000 |

Peel strength AI |

≥80N/25mm |

ASTM D 1000 |

Structure

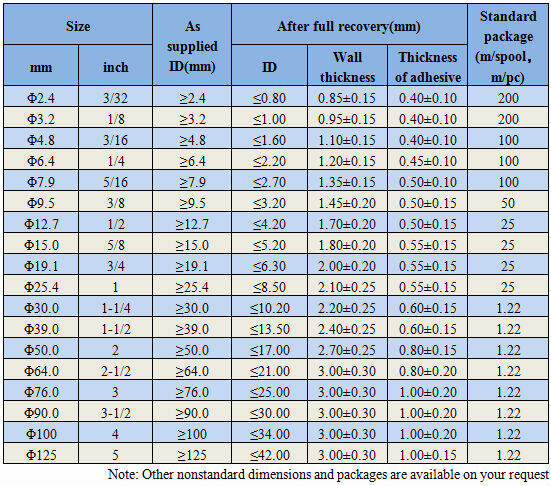

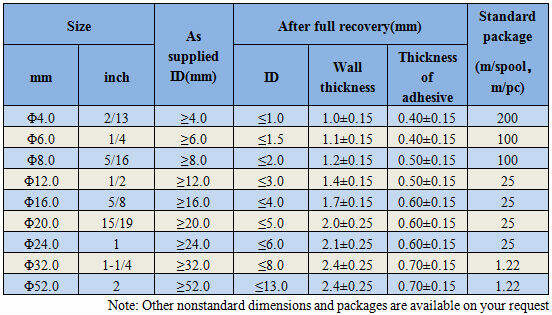

Dimensions

SBRS-125G(3X) Dimensions