New Energy Vehicles Shaft Grounding Ring Alloy Nickel Coated for Safe Protection Bearings Electric Drives Model V-562 Static

Description

Volsun’s New Energy Vehicles Shaft Grounding Ring Alloy Nickel Coated Model V-562 Static is a reliable, easy-to-install solution designed to protect bearings and electric drives in modern electric vehicles. Built to meet the demands of high-performance automotive environments, this grounding ring offers consistent, long-lasting protection against shaft currents and electrostatic discharge that can damage bearings and reduce component life.

Constructed from a durable alloy and finished with a nickel coating, the V-562 combines strength and corrosion resistance. The nickel plating provides a smooth, conductive surface that resists wear and oxidation, ensuring reliable contact with the shaft over extended service intervals. The alloy core gives the ring structural stability so it maintains shape and performance under vibration, heat, and mechanical stress typically found in electric drive systems.

The ring’s design prioritizes effective grounding while minimizing maintenance. It features a robust contact element that maintains stable electrical connection to the shaft, diverting harmful stray currents safely to ground. This reduces the risk of fluting, pitting, and premature failure of bearings, helping to extend the life of both bearings and associated electric drive components. The grounding path is engineered to handle typical shaft current magnitudes encountered in new energy vehicles, ensuring safe dissipation without impact to drive performance.

Installation is straightforward, saving time for service technicians and reducing downtime. The V-562 is sized and shaped to fit common shaft profiles used in electric motors and gearboxes. Its compact form factor allows integration within tight spaces while offering accessible connection points for grounding leads. Clear mounting features and a user-focused design make alignment and securing fast and reliable.

Durability and safety are central to Volsun’s design. The nickel-coated alloy resists environmental challenges such as moisture, dirt, and salt commonly found on roads, while the construction withstands repeated starts, stops, and torque fluctuations. These traits make V-562 suitable for passenger EVs, commercial electric vehicles, and other battery-powered mobility platforms that demand robust electrical protection.

Beyond protection, the grounding ring supports smoother operation. By preventing electrical damage to bearings, it helps maintain low friction, reduce noise, and preserve mechanical efficiency. This contributes to consistent drive performance, lower maintenance costs, and improved vehicle reliability over the life of the drivetrain.

Volsun’s Model V-562 Static Shaft Grounding Ring Alloy Nickel Coated is an effective, low-maintenance choice for safeguarding bearings and electric drives in new energy vehicles. Its durable construction, reliable conductivity, and easy installation make it an essential component for engineers and technicians focused on longevity and safety in electrified drivetrains

Volsun VS-RD Series Shaft Grounding Rings

VS-RD series shaft grounding rings are composed of conductive fibers and metal bodies and are used for electric corrosion protection of variable frequency motors and their coupling equipment. VS-RD series conductive rings can reduce the potential induction between the bearing and the grounded chassis, effectively solve the phenomenon of electrical corrosion caused by shaft current, and protect the bearing from damage

Item |

Test Data |

Test Standard |

Static resistance |

<1Ω |

/ |

Dynamic resistance |

≤10Ω |

/ |

Fiber pull-off force |

≥100·30s |

/ |

Salt spray test |

No fiber damage |

/ |

Durability test |

A3 |

/ |

High temperature test |

≥120h |

/ |

Low temperature test |

≥15times |

/ |

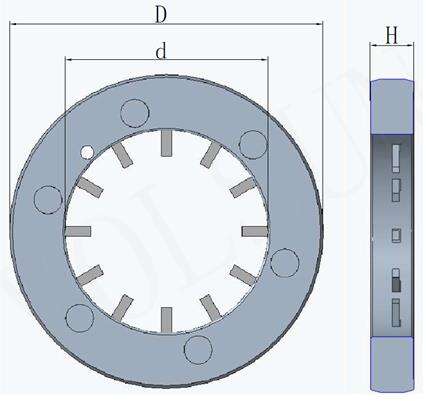

Dimensions

OD - mm |

ID - mm |

Height - mm |

Applicable shaft diameter - mm |

30 |

15 |

7 |

10 |

38 |

19 |

7 |

13 |

38 |

22 |

7 |

18 |

40 |

24 |

7 |

18 |

47 |

31 |

7 |

25 |

49 |

32 |

7 |

26 |

50 |

30 |

7 |

24 |

50 |

31 |

7 |

25 |

53 |

30 |

7 |

25 |

53 |

36 |

7 |

30 |

55 |

39 |

7 |

35 |

57 |

36 |

7 |

30 |

60 |

44 |

7 |

38 |

62 |

41 |

7 |

35 |

70 |

46 |

7 |

40 |

72 |

49 |

7 |

43 |

75 |

58 |

7 |

52 |

78 |

58 |

7 |

52 |

Note:Special size and packing are available as request

Suzhou Volsun Electronics Technology Co., Ltd. was founded in 2006. We keep focusing on the R&D, production and sales in insulation, sealing & protection solutions

Volsun has a modern quality management system, which has passed a series of quality system certification such as IATF16949, ISO9001 etc

FAQ

A: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product orders

A: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packaging

A: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your products

A: It depends on the model, we produce more than 1500 tons of rubber materials per month

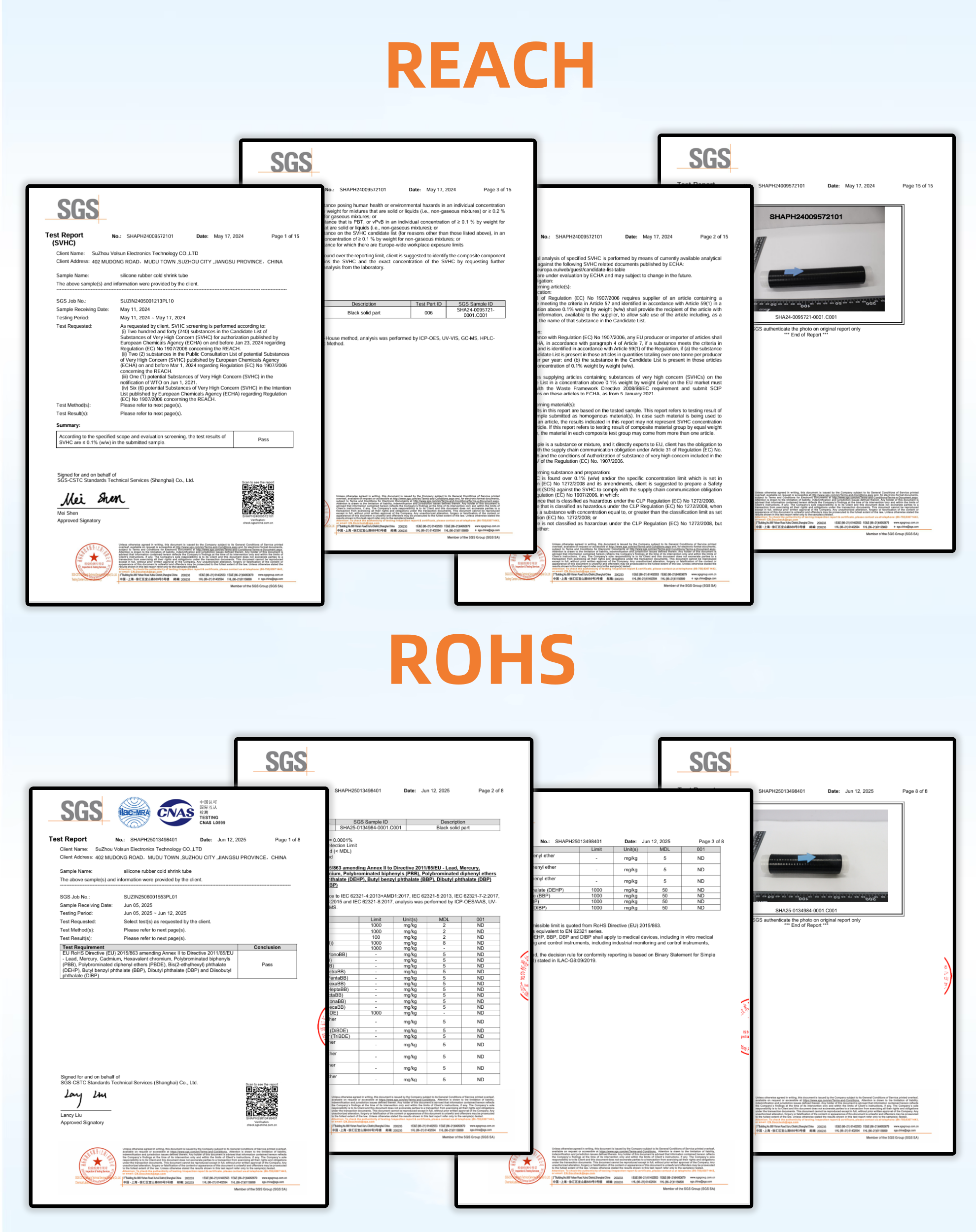

Q 5. What kind of certificates do you have

A1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk order

A1: We provide pre-production samples to all customers before mass production if needed

A3: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 7: Can you provide customized service

A: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements