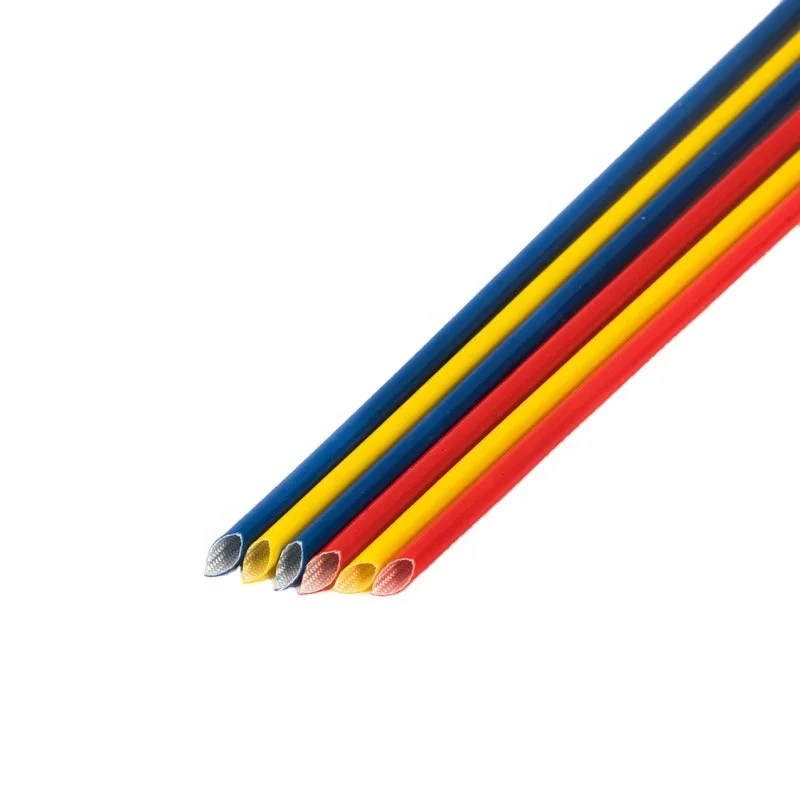

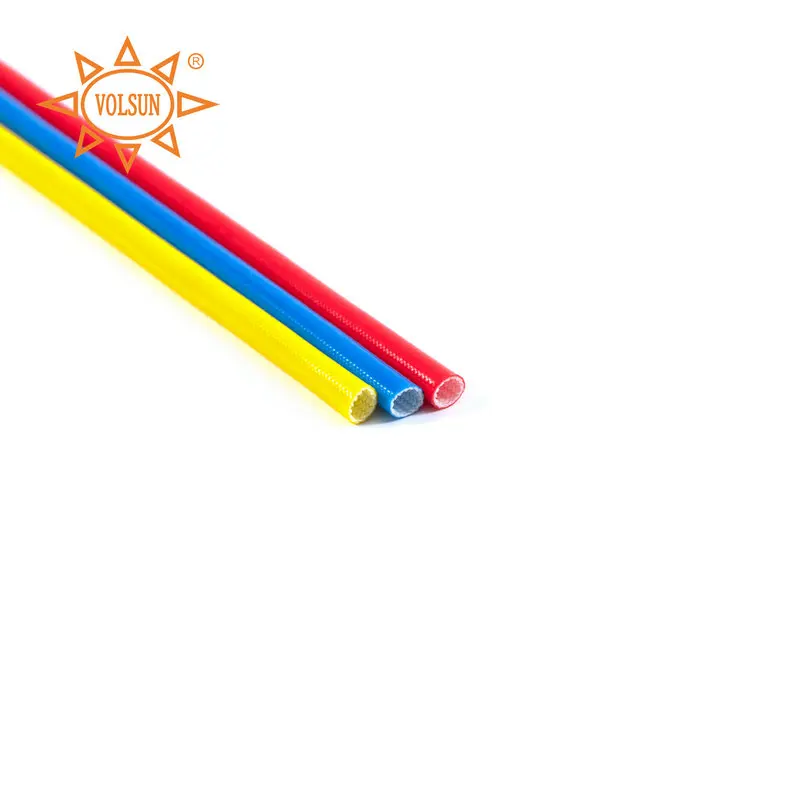

High Temperature Resistant Insulation Silicone Fiberglass Sleeve for New Energy Motor Winding Protection

Description

Introducing, the Volsun’s High Temperature Resistant Insulation Silicone Fiberglass Sleeve, a must-have for protecting your new energy motor windings. Designed with advanced technology and high-quality materials, this sleeve provides superior heat resistance to ensure your motor stays safe and efficient.

Made from a combination of silicone and fiberglass, this sleeve is able to withstand extreme temperatures without compromising its performance. Whether your motor is operating at high speeds or under heavy loads, the Volsun sleeve will provide reliable insulation and protection against heat damage.

Installing the Volsun sleeve on your motor windings is quick and easy, thanks to its flexible design and durable construction. Simply slide the sleeve over the winding and secure it in place for immediate protection. With a snug fit and excellent insulation properties, you can trust that your motor will continue to operate at its best for years to come.

In addition to its high temperature resistance, the Volsun sleeve also offers excellent electrical insulation properties. This ensures that your motor windings are protected from electrical currents and can operate safely and efficiently. With the Volsun sleeve, you can have peace of mind knowing that your motor is well-protected against a range of potential risks.

Whether you are working on a new energy project or simply need to upgrade the insulation on your existing motor windings, the Volsun’s High Temperature Resistant Insulation Silicone Fiberglass Sleeve is the perfect solution. With its reliable performance, easy installation, and exceptional durability, this sleeve is a great investment for any motor owner.

Don't let high temperatures and electrical currents damage your motor windings – protect them with the Volsun’s High Temperature Resistant Insulation Silicone Fiberglass Sleeve today. Trust in the Volsun brand for top-quality products that deliver exceptional performance and long-lasting protection. Your motor will thank you for it

UL high voltage Silicone rubber fiberglass sleeve knitted fiberglass sleeve for wiring harness protection

Items |

Technical Parameters |

Reference Standard |

Appearance |

No glue leakage, cracking, etc |

GB/T 7113.1-2014 |

Coating hydrolysis |

No coating displacement, adhesion, et |

GB/T 7113.2 |

Cold bending test |

-40℃,4h,No cracks, coating peeling and delamination |

IEC60684 |

Temperature |

-40℃~200℃ |

UL1441 |

Flame retardant rating |

HB |

UL94 |

Breakdown voltage |

Reference standard |

GB/T 1408-2016 |

Heat Resistance |

250℃±5, 24h, No droplets, no flow marks, no cracking |

JB/T 7093 2015 |

Dimensions

I.D. - mm |

Wall thickness - mm |

Wall Thickness(mm) |

Package |

|||||

Size |

Tolerance |

1500V |

2500V |

4000V |

7000V |

M/Roll |

||

Φ2.0 |

-0.10~0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||

Φ2.5 |

-0.10~0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||

Φ3.0 |

-0.10~0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||

Φ3.5 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||

Φ4.0 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||

Φ4.5 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||

Φ5.0 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||

Φ5.5 |

-0.10~0.40 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.60±0.1 |

100 |

||

Φ6.0 |

-0.10~0.40 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.60±0.1 |

100 |

||

Φ7.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.60±0.1 |

100 |

||

Φ8.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.65±0.1 |

50 |

||

Φ9.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.65±0.1 |

50 |

||

Φ10.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||

Φ11.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||

Φ12.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||

Φ13.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||

Φ14.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||

Φ15.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||

We don't list all sizes here. Diameter 16mm-25mm can also produce

Company Show

Up to now, Volsun cooperated with customers from 88 countries, we offer suitable sealing, waterproof solutions for some well-know enterprises in communication, Automobile, Power industry etc

Packing & Delivery

Trade terms |

FOB, EXW, CIF, DDU, DDP, CFR |

Payment terms |

T/T, L/C, Negotiable |

MOQ |

100M |

Supply capability |

1,000,000 mts per month |

Lead time |

Usually 2-3 working days |

Shipment |

Express, Air, Sea |

Port |

Shanghai, Ningbo, Shenzhen |

Sample availability |

Yes |

Sample time |

Usually 1-2 days |

Packaging |

Normal: Plastic bag & Carton & Pallet Special: Customized packing |

Certificate

Abroad Exhibition