Description

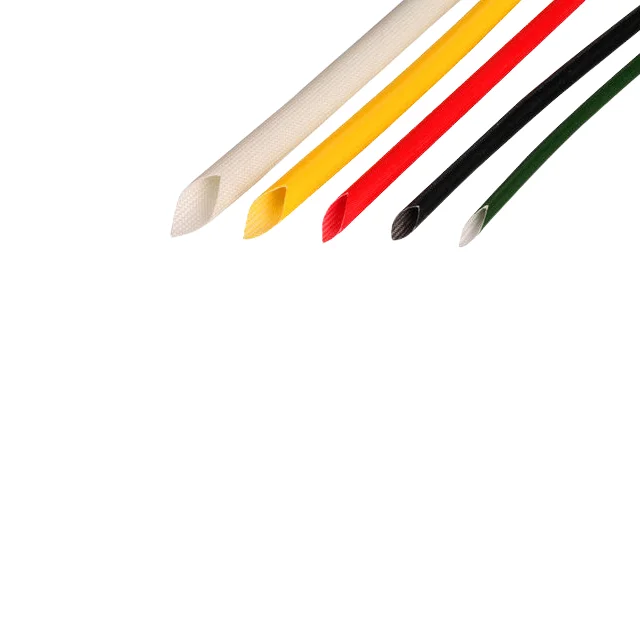

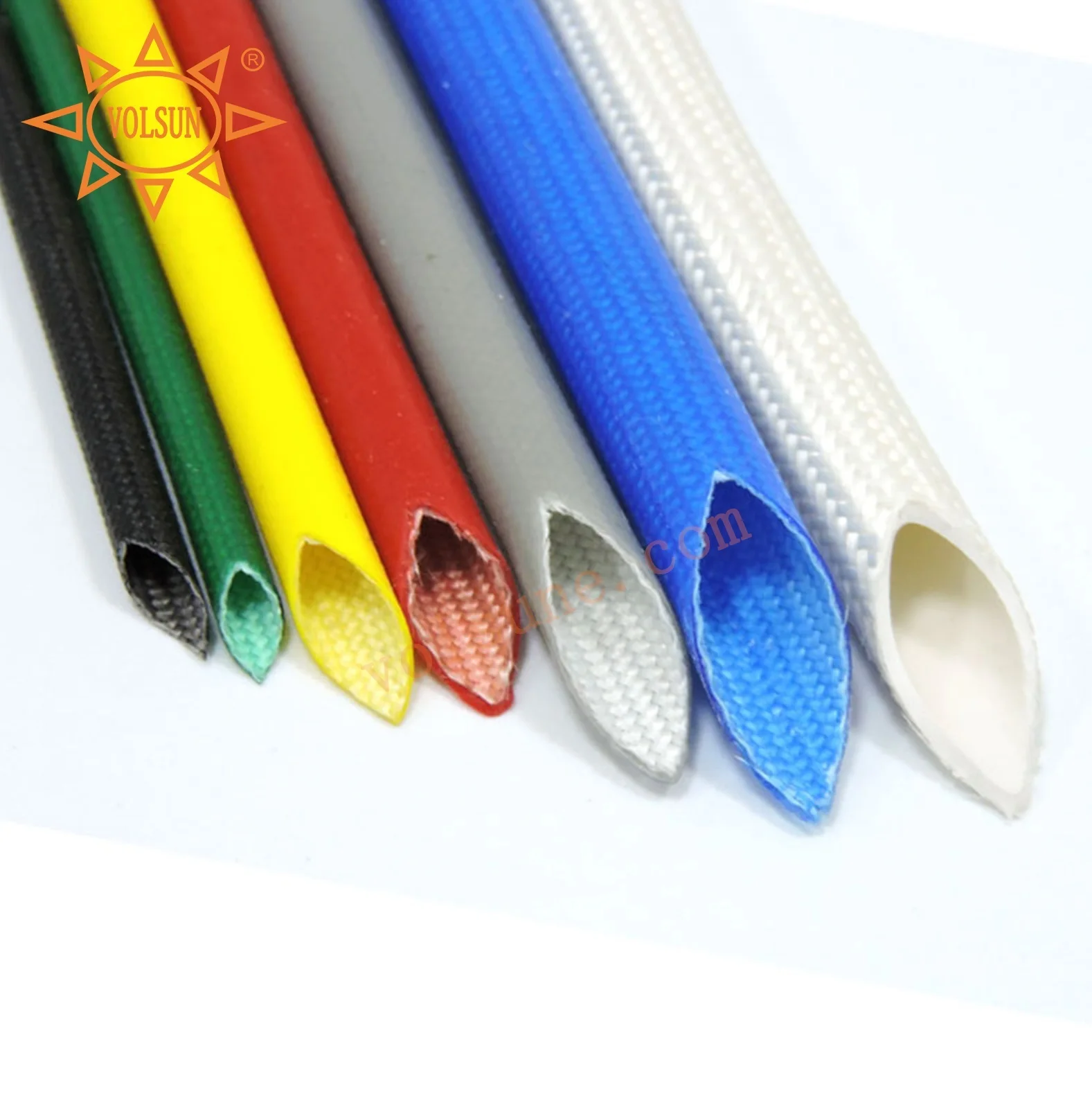

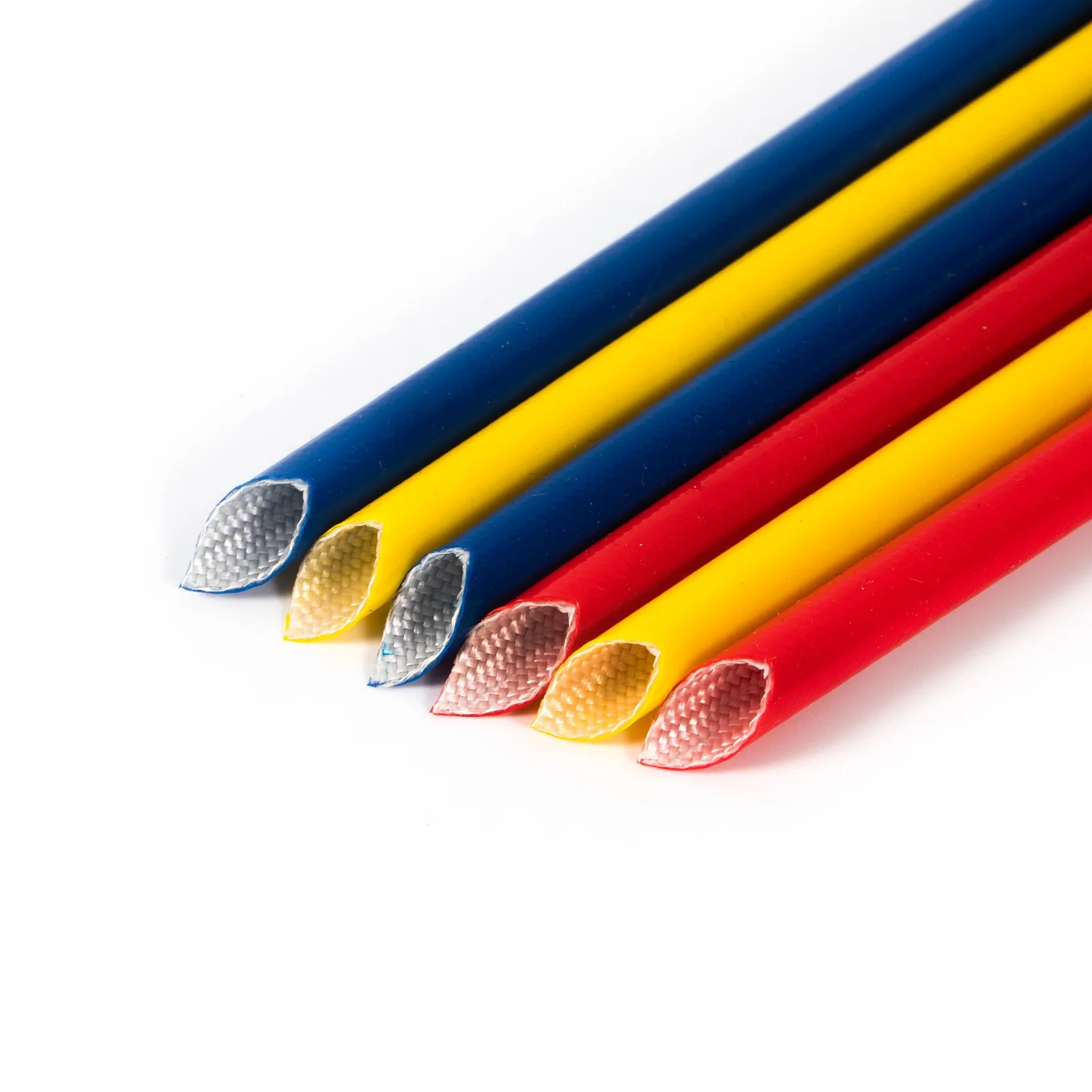

Introducing, Volsun’s Heat Resistant Wire Sleeving, the ultimate solution for protecting your wires and cables in high-temperature environments. Made from durable acrylic coated braided fiberglass, this sleeving is designed to withstand extreme heat without compromising the integrity of your wiring.

With temperatures reaching up to 500°F, Volsun’s Heat Resistant Wire Sleeving provides reliable protection for a variety of applications including automotive, aerospace, and industrial settings. Its acrylic coating not only enhances its heat resistance but also provides extra durability and flexibility, allowing for easy installation and maintenance.

The braided fiberglass construction of this wire sleeving offers excellent abrasion resistance, making it ideal for use in harsh conditions where wires are constantly exposed to friction and wear. Its high tensile strength and flexibility ensure that your wires remain securely protected while maintaining their mobility.

Volsun’s Heat Resistant Wire Sleeving is available in various sizes and lengths to suit your specific needs. Whether you're looking to protect a single wire or a bundle of cables, this sleeving can be easily cut to size and custom-fit to your application. The sleek black finish also adds a professional look to your wiring, making it ideal for both commercial and industrial installations.

In addition to its heat resistance, Volsun’s Heat Resistant Wire Sleeving also provides insulation against electrical currents, protecting your wires from potential damage due to short circuits or electrical interference. This added layer of safety ensures that your wiring remains reliable and efficient in any environment.

Trust Volsun to deliver quality and performance with our Heat Resistant Wire Sleeving. Backed by years of experience and a commitment to innovation, Volsun is your go-to source for high-quality wire protection solutions. Keep your wiring secure and functional in high-temperature settings with Volsun’s Heat Resistant Wire Sleeving

UL high voltage Silicone rubber fiberglass sleeve knitted fiberglass sleeve for wiring harness protection

Items |

Technical Parameters |

Reference Standard |

Appearance |

No glue leakage, cracking, etc |

GB/T 7113.1-2014 |

Coating hydrolysis |

No coating displacement, adhesion, etc |

GB/T 7113.2 |

Cold bending test |

-40℃,4h,No cracks, coating peeling and delamination |

IEC60684 |

Temperature |

-40℃~200℃ |

UL1441 |

Flame retardant rating |

HB |

UL94 |

Breakdown voltage |

Reference standard |

GB/T 1408-2016 |

Heat Resistance |

250℃±5, 24h, No droplets, no flow marks, no cracking |

JB/T 7093 2015 |

Dimensions

I. D. - mm |

Wall thickness - mm |

Wall Thickness(mm) |

Package |

|||||||

Size |

Tolerance |

1500V |

2500V |

4000V |

7000V |

M/Roll |

||||

Φ2.0 |

-0.10~0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||||

Φ3.0 |

-0.10~0.25 |

0.35±0.1 |

0.40±0.1 |

0.45±0.1 |

0.5±0.1 |

100 |

||||

Φ4.0 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||||

Φ5.0 |

-0.10~0.35 |

0.4±0.1 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

100 |

||||

Φ6.0 |

-0.10~0.40 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.60±0.1 |

100 |

||||

Φ7.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.60±0.1 |

100 |

||||

Φ8.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.65±0.1 |

50 |

||||

Φ9.0 |

-0.10~0.50 |

0.45±0.1 |

0.50±0.1 |

0.55±0.1 |

0.65±0.1 |

50 |

||||

Φ10.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||||

Φ12.0 |

-0.20~0.70 |

0.50±0.15 |

0.55±0.15 |

0.65±0.15 |

0.7±0.15 |

50 |

||||

Φ13.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

Φ14.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

Φ15.0 |

-0.30~0.80 |

0.55±0.15 |

0.60±0.15 |

0.70±0.15 |

0.75±0.15 |

50 |

||||

We don't list all sizes here, other sizes are available on request

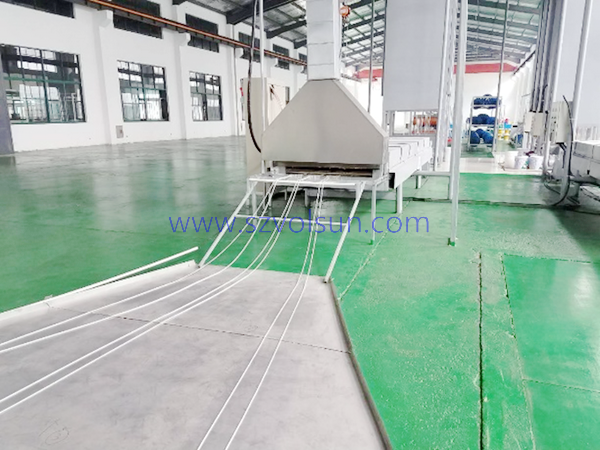

Company Show

Up to now, Volsun cooperated with customers from 88 countries, we offer suitable sealing, waterproof solutions for some well-know enterprises in communication, Automobile, Power industry etc

Packing & Delivery

Trade terms |

FOB, EXW, CIF, DDU, DDP, CFR |

Payment terms |

T/T, L/C, Negotiable |

MOQ |

100M |

Supply capability |

1,000,000 mts per month |

Lead time |

Usually 2-3 working days |

Shipment |

Express, Air, Sea |

Port |

Shanghai, Ningbo, Shenzhen |

Sample availability |

Yes |

Sample time |

Usually 1-2 days |

Packaging |

Normal: Plastic bag & Carton & Pallet Special: Customized packing |

Certificate

Abroad Exhibition