Description

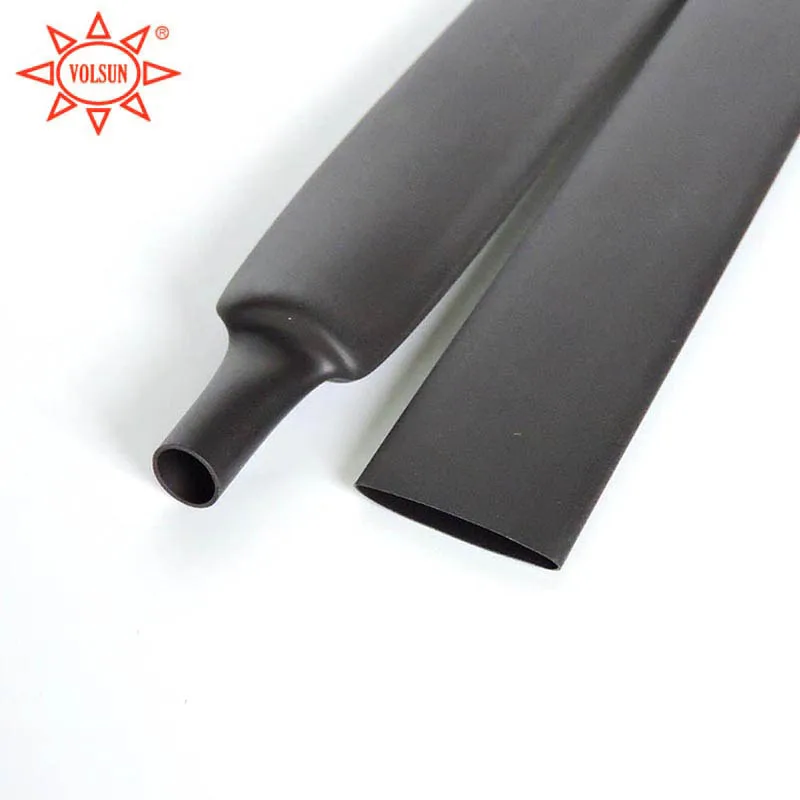

The Volsun Flexible Glue Lined Heat Shrink Tube is a reliable and easy-to-use solution for protecting and insulating wires and cables. It comes in two shrink ratios: 3:1 and 4:1, which means the tube will shrink down to one-third or one-quarter of its original size when heated. This makes it perfect for fitting over connectors, joints, and cables of different sizes, providing a tight and secure seal.

Made with a special glue-lined inside, the Volsun heat shrink tube offers excellent waterproof and airtight protection. When heated, the glue melts and sticks firmly to the wires and cables, keeping out moisture, dust, and dirt. This not only protects the electrical connections but also helps to prevent corrosion and damage caused by water or other elements. The glue lining also helps improve the strength and durability of the tube, making it less likely to crack or break over time.

The tube is very flexible, which makes it easy to work with even in tight spaces or on curved surfaces. It bends easily without losing its shape or protective qualities, making it a great choice for automotive, marine, electronics, and home DIY projects. Whether you need to protect wires in a car engine, repair cables on a boat, or organize wiring in your home, Volsun’s heat shrink tubes provide a neat and professional finish.

To use the Volsun Flexible Glue Lined Heat Shrink Tube, simply slide it over the area you want to protect and apply heat with a heat gun or lighter. The tube will shrink tightly around the cable or connection, and the glue lining will bond to the surface, creating a strong seal. The high-quality material ensures fast and even shrinking without burning or melting, so you get a clean and smooth result every time.

The Volsun heat shrink tubes are available in various sizes to fit different cable diameters, making it easy to find the right tube for your project. They are also resistant to chemicals, abrasion, and extreme temperatures, ensuring long-lasting protection in harsh environments.

The Volsun Flexible Glue Lined Heat Shrink Tube 3:1 and 4:1 is a practical and trustworthy product for anyone needing to protect and insulate wires and cables. Its strong glue lining, flexible design, and wide size range make it a must-have tool for electrical work and repairs

* Soft, non-flame retardant, environmental protection, UV resistance

* Shrinkage temperature: 70℃ ~ 100℃

* Operating temperature: -45℃ ~ 110℃ - transparent type: -45℃ ~ 105℃

* Environmental protection standard: RoHS

* Standard color: black, white, red, yellow, green, blue, transparent, other colors can be customized

Item |

Typical Value |

Test Method |

Tensile Strength |

≥12MPa |

ASTM D 2671 |

Elongation at Break |

≥300% |

ASTM D 2671 |

Tensile strength after thermal aging |

≥7.3MPa |

UL224 158℃×168h |

Elongation at break after thermal aging |

≥200% |

UL224 158℃×168h |

Breakdown strength |

≥15kV/mm |

IEC 243 |

Volume resistivity |

≥1014Ω/cm |

IEC 93 |

Item |

Typical Value |

Test Method |

Softening point |

95℃ |

ASTM E 28 |

Water absorption |

<0.2% |

ASTM D 570 |

Peel strength - adhesive to PE |

≥120N/25mm |

ASTM D 1000 |

Peel strength |

≥80N/25mm |

ASTM D 1000 |

Size

3:1 Shrink Ratio

|

Supplied ID - mm |

Sizes after fully recovered - mm |

Standard Packing |

||||

Inner diameter |

Total wall thickness Black/Colored

|

adhesive layer wall thickness Black/Colored

|

Meter/Roll, Meter/PCS

|

||||

Φ1.6 |

≥1.6 |

≤0.60 |

0.65±0.15 |

0.30±0.10 |

200/1.22 |

||

Φ2.4 |

≥2.4 |

≤1.00 |

0.70±0.15 |

0.35±0.10 |

200/1.22 |

||

Φ3.2 |

≥3.2 |

≤1.30 |

0.90±0.30 |

0.40±0.20 |

200/1.22 |

||

Φ4.8 |

≥4.8 |

≤1.70 |

≥0.75 / 1.05±0.30 |

0.30±0.10 / 0.40±0.20 |

100/1.22 |

||

Φ6.4 |

≥6.0 |

≤2.50 |

≥0.75 / 1.25±0.30 |

0.40±0.10 / 0.45±0.20 |

100/1.22 |

||

Φ7.9 |

≥7.9 |

≤2.80 |

≥0.95 / 1.30±0.30 |

0.40±0.10 / 0.45±0.20 |

100/1.22 |

||

Φ9.5 |

≥9.0 |

≤3.20 |

≥0.95 / 1.45±0.30 |

0.40±0.10 / 0.50±0.20 |

50/1.22 |

||

Φ12.7 |

≥12.0 |

≤4.60 |

≥1.10 / 1.70±0.30 |

0.50±0.10 / 0.50±0.20 |

25/1.22 |

||

Φ15.0 |

≥15.0 |

≤5.60 |

≥1.20 / 1.80±0.30 |

0.50±0.10 / 0.55±0.30 |

25/1.22 |

||

Φ19.1 |

≥19.0 |

≤6.80 |

1.95±0.30 |

0.50±0.10 / 0.60±0.30 |

25/1.22 |

||

Φ22.0 |

≥22.0 |

≤7.50 |

1.95±0.30 |

0.60±0.30 |

25/1.22 |

||

Φ25.4 |

≥24.0 |

≤9.50 |

2.05±0.40 |

0.60±0.10 / 0.60±0.30 |

25/1.22 |

||

Φ30.0 |

≥30.0 |

≤12.0 |

2.20±0.40 |

0.60±0.10 / 0.65±0.30 |

25/1.22 |

||

Φ39.0 |

≥39.0 |

≤15.0 |

2.50±0.40 |

0.75±0.30 |

25/1.22 |

||

Φ50.0 |

≥50.0 |

≤19.0 |

2.80±0.40 |

0.90±0.30 |

25/1.22 |

||

Φ60.0 |

≥60.0 |

≤23.0 |

2.80±0.40 |

1.00±0.30 |

25/1.22 |

||

Φ70.0 |

≥70.0 |

≤24.0 |

2.80±0.40 |

1.05±0.40 |

25/1.22 |

||

Φ80.0 |

≥80.0 |

≤27.0 |

2.90±0.50 |

1.05±0.40 |

25/1.22 |

||

Φ90.0 |

≥90.0 |

≤33.0 |

2.90±0.50 |

1.05±0.40 |

25/1.22 |

||

Φ100.0 |

≥100 |

≤34.0 |

3.10±0.50 |

1.00±0.40 |

25/1.22 |

||

Φ120.0 |

≥120 |

≤42.0 |

3.55±0.50 |

1.20±0.40 |

25/1.22 |

||

Φ125.0 |

≥125 |

≤42.0 |

3.65±0.50 |

1.20±0.40 |

25/1.22 |

||

Φ130.0 |

≥130 |

≤44.0 |

3.65±0.50 |

1.20±0.40 |

25/1.22 |

||

Size

4:1 Shrink Ratio

|

Supplied ID - mm |

Sizes after fully recovered - mm |

Standard Packing |

||||

Inner diameter |

Total wall thickness

Black/Colored

|

adhesive layer wall thickness

Black/Colored

|

Meter/Roll, Meter/PCS

|

||||

Φ4.0 |

≥4.0 |

≤1.0 |

1.05±0.3 |

0.40±0.3 |

200 |

||

Φ6.0 |

≥6.0 |

≤1.50 |

1.15±0.3 |

0.40±0.3 |

100 |

||

Φ8.0 |

≥8.0 |

≤2.0 |

1.55±0.3 |

0.50±0.3 |

100 |

||

Φ12.0 |

≥12.0 |

≤3.0 |

1.75±0.3 |

0.50±0.3 |

50/1.22 |

||

Φ16.0 |

≥16.0 |

≤4.0 |

2.00±0.3 |

0.60±0.3 |

25/1.22 |

||

Φ20.0 |

≥20.0 |

≤5.0 |

2.30±0.4 |

0.60±0.3 |

25/1.22 |

||

Φ24.0 |

≥24.0 |

≤6.0 |

2.60±0.4 |

0.60±0.3 |

25/1.22 |

||

Φ32.0 |

≥32.0 |

≤8.0 |

3.00±0.5 |

0.70±0.3 |

25/1.22 |

||

Φ52.0 |

≥52.0 |

≤13.0 |

3.35±0.5 |

0.70±0.3 |

25/1.22 |

||

Φ72.0 |

≥68.0 |

≤24.0 |

3.35±0.5 |

0.70±0.3 |

25/1.22 |

||

Trade terms |

FOB, EXW, CIF, DDU, DDP, CFR |

Payment terms |

T/T, L/C, Negotiable |

Supply capability |

100,000 meters per month |

Lead time |

Usually 5-7 working days |

Shipment |

Express, Air, Sea |

Port |

Shanghai, Ningbo, Shenzhen |

Sample availability |

Yes |

Sample time |

Usually 1-2 days |

Packaging |

Normal: Plastic bag & Carton & Pallet Special: Customized packing |

Suzhou Volsun Electronics Technology Co., Ltd. was founded in 2006. We keep focusing on the R&D, production and sales in insulation, sealing & protection solutions

Quality is our culture. Volsun has a modern quality management system, which has passed a series of quality system certification such as IATF16949, ISO9001 etc

Up to now, Volsun cooperated with customers from 88 countries, we offer suitable sealing, waterproof solutions for some well-know enterprises in communication, Automobile, Power industry etc

A: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product orders

A: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packaging

A: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your products

A: It depends on the model, we produce more than 1500 tons of rubber materials per month

Q 5. What kind of certificates do you have

A1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk order

A1: We provide pre-production samples to all customers before mass production if needed

A3: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 7: Can you provide customized service

A: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements.