Shaft Grouning Rings Carbon Fiber Conductive Brush Shaft Grounding Ring for Industrical Motors

Description

Introducing, the Volsun’s Conductive Ring Carbon Fiber Conductive Brush Shaft Grounding Ring for Overhead Cranes. This innovative product is designed to provide a safe and reliable way to ground overhead crane systems, ensuring optimal performance and eliminating the risk of static electricity buildup.

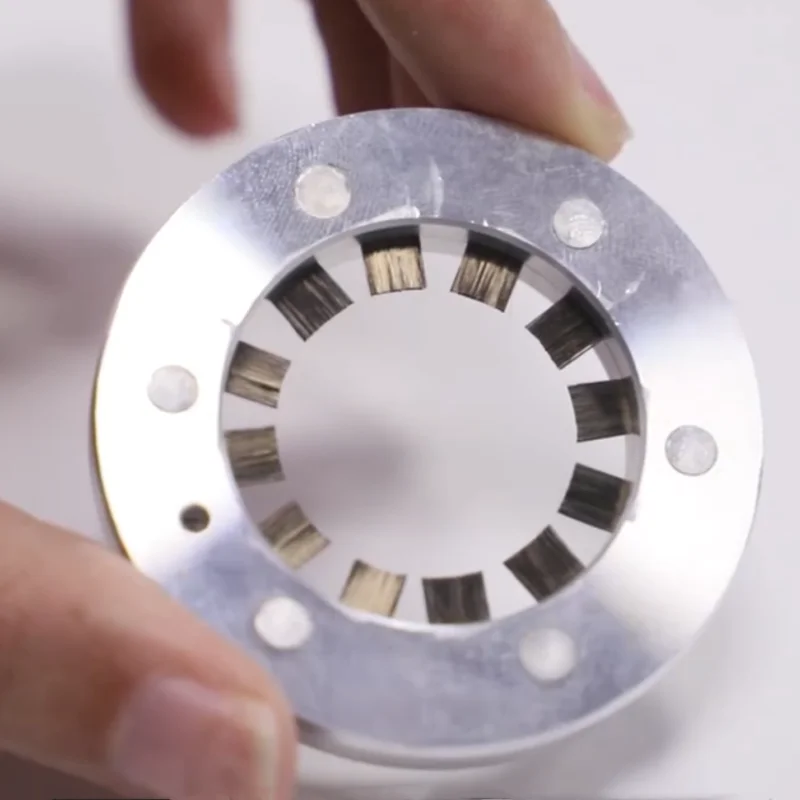

The Volsun’s Conductive Ring features a durable carbon fiber construction that is both lightweight and highly conductive. This allows for efficient grounding of the crane system, preventing static discharge and protecting sensitive equipment from damage.

The brush shaft design of the grounding ring ensures continuous contact with the crane runway, providing a consistent grounding path for the system. This helps to maintain a stable electrical connection and reduce the risk of electrical malfunctions or interference.

Installation of the Volsun’s Conductive Ring is quick and easy, requiring no special tools or equipment. Simply attach the grounding ring to the crane runway using the included mounting hardware, and connect it to the crane system using the provided cables. The compact and streamlined design of the grounding ring allows for easy integration into existing crane systems without disrupting operations.

With the Volsun’s Conductive Ring Carbon Fiber Conductive Brush Shaft Grounding Ring, you can have peace of mind knowing that your overhead crane system is properly grounded and protected from static electricity buildup. Say goodbye to costly downtime and repairs due to electrical issues, and trust in the reliability and performance of Volsun's innovative grounding solution.

Don't compromise on safety and performance when it comes to your overhead crane system. Choose the Volsun’s Conductive Ring Carbon Fiber Conductive Brush Shaft Grounding Ring and enjoy the benefits of a secure and efficient grounding solution. Invest in quality and reliability with Volsun, the trusted brand for overhead crane accessories

Volsun VS-RD Series Shaft Grounding Rings

VS-RD series conductive rings solve the problem of motor shaft electro-corrosion by bypass grounding. It is composed of conductive fibers, metal bodies, etc., and is used for electro-corrosion protection of variable frequency motors and their coupled equipment. VS-RD series conductive rings can reduce the induced potential between the bearing and the grounded housing, effectively reduce the damages of electro-corrosion caused by shaft current, protect motor bearings to ensure long-term and stable operation of the motor

Item |

Test Data |

Test Standard |

Static resistance |

<1Ω |

/ |

Dynamic resistance |

≤10Ω |

/ |

Fiber pull-off force |

≥100·30s |

/ |

Salt spray test |

No damage to fibers |

/ |

Durability test - Water cooling/Oil cooling |

<0.5mm/30Wkm

<0.2mm/30Wkm

|

/ |

High temperature test |

See enterprise standards |

/ |

Low temperature test |

See enterprise standards |

/ |

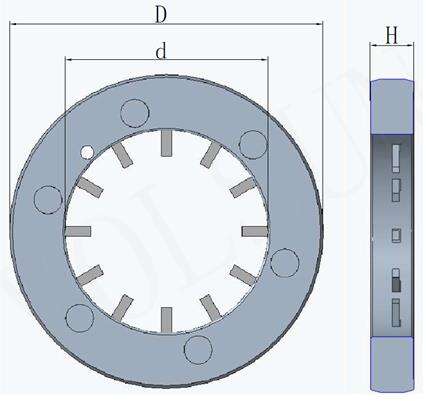

Dimensions

O. D - mm |

Matching Shaft Diameter - mm |

Height - mm |

30 |

10 |

≥7 |

35 |

17 |

≥7 |

38 |

13 |

≥7 |

40 |

18 |

≥7 |

47 |

25 |

≥7 |

50 |

25 |

≥7 |

52 |

26 |

≥7 |

58 |

39 |

≥7 |

60 |

40 |

≥7 |

62 |

36 |

≥7 |

66 |

41.5 |

≥7 |

70 |

40 |

≥7 |

72 |

43 |

≥7.5 |

78 |

54 |

≥7.5 |

85 |

59 |

≥7.5 |

92 |

70 |

≥7.5 |

108 |

80 |

≥7.5 |

128 |

79.5 |

≥7.5 |

Note:The other sizes and packing are available as request

Packing & Delivery

FAQ

A: We accept T/T 50% deposit and 50% balance against B/L or L/C copy at sight, also accept Western Union, VISA and Paypal

Q 2. What is the normal lead time for product orders

A: The average lead time for prototype/first piece is 7~10 days, if tooling is involved, the lead time for production tooling is 10 days, and the average production time after sample approval is 2-3 weeks

Q 3. What is your standard packaging

A: All goods will be packed in cartons and loaded on pallets. Special packing methods are acceptable when needed

Q 4. Can you tell us the monthly production capacity of your products

A: It depends on the model, we produce more than 1500 tons of rubber materials per month

Q 5. What kind of certificates do you have

A1: We have ISO9001:2015, IATF16949:2016, ISO14001:2015, ISO45001:2018 certified

A2: We have various rubber compounds approved by UL, ROHS and REACH

Q6: How to check the quality of bulk order

A1: We provide pre-production samples to all customers before mass production if needed

A3: We accept third-party inspection, such as SGS, TUV, INTERTEK, BV, etc

Q 7: Can you provide customized service

A: Yes, we accept customization and can produce products in different sizes, packaging, colors according to requirements.