* Excellent mechanical properties and extensibility

* Excellent thermal conductivity and aging resistance

* Low viscosity, self-leveling, excellent drilling ability

* Low modulus, low stress, good adhesion to both metals and plastics

Volsun’s 3.0w/mk Thermal Potting Compound is a high-performance silicone resin potting compound designed to efficiently transfer heat away from electronic components. This AB glue is specially formulated with a thermal conductivity of 3.0w/mk, making it ideal for applications where heat dissipation is critical.

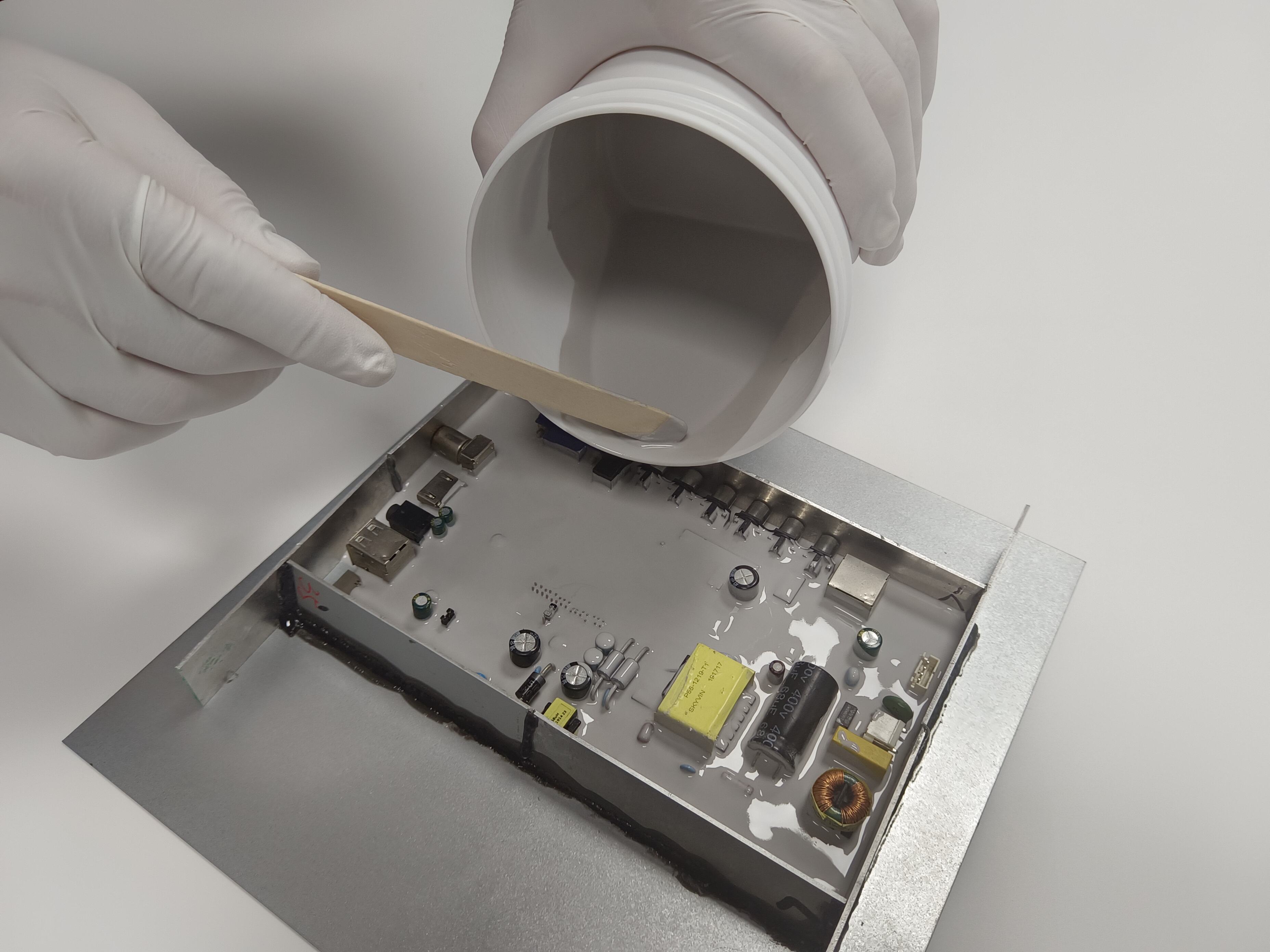

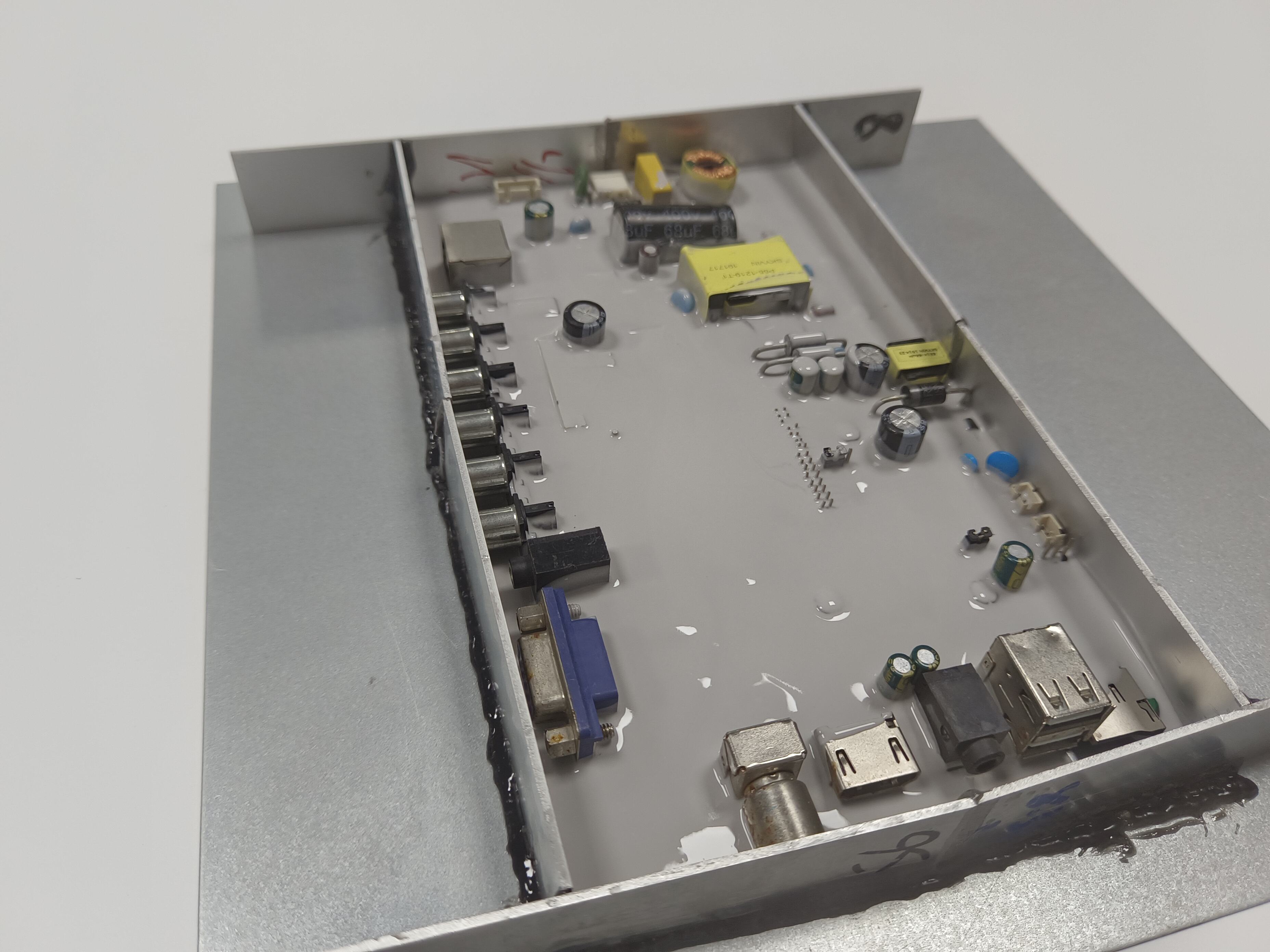

The Volsun’s Thermal Potting Compound is easy to mix and apply, making it perfect for both professional and DIY projects. Simply combine the two components in equal parts, mix thoroughly, and pour the compound over the electronic component to create a durable, heat-resistant seal. Once cured, the potting compound forms a protective barrier that shields the electronic components from dust, moisture, and other environmental factors.

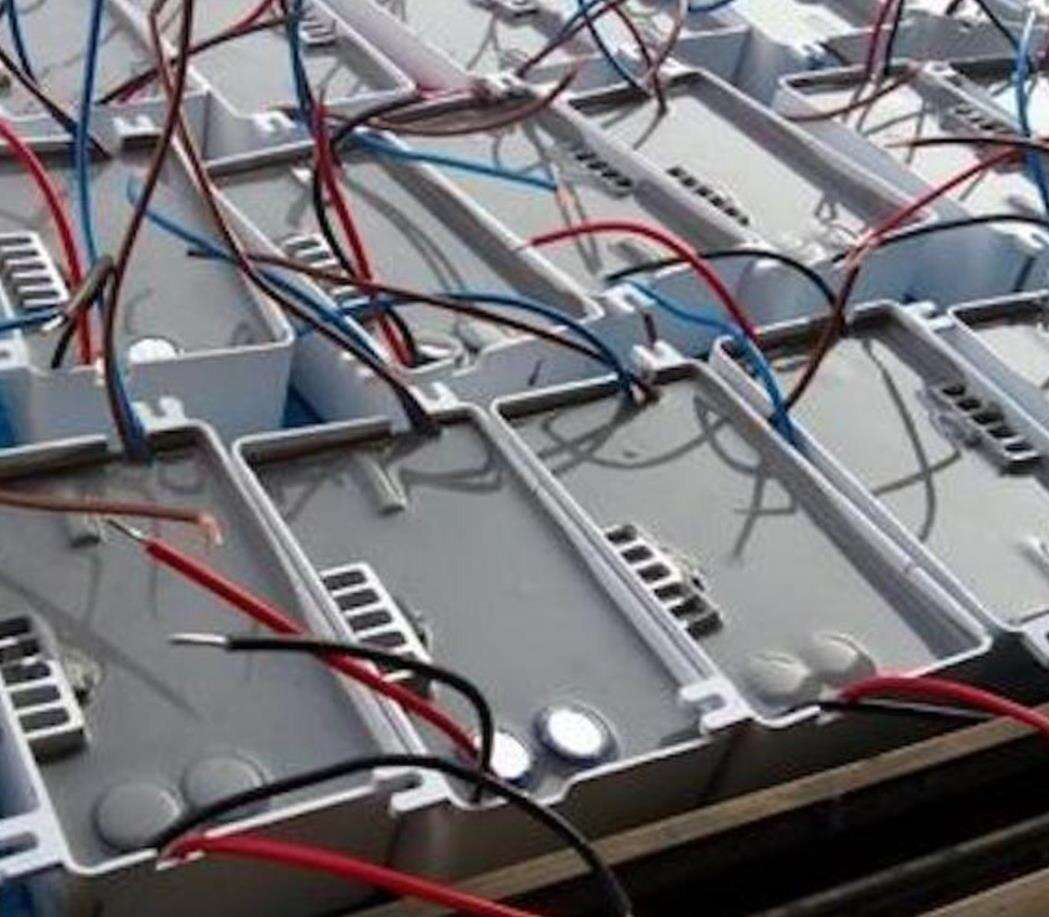

This silicone thermal conductive resin is highly versatile and can be used in a wide range of applications, including LED lighting, power supplies, automotive electronics, and more. Its low viscosity allows it to easily flow into tight spaces and intricate designs, ensuring optimal coverage and heat transfer. The Volsun’s Thermal Potting Compound is also flame-retardant and has excellent adhesion properties, providing long-lasting protection and performance.

Whether you are looking to improve the thermal management of your electronic devices or need a reliable potting compound for your next project, Volsun’s 3.0w/mk Thermal Potting Compound is the perfect solution. With its high thermal conductivity, ease of use, and durability, this AB glue is sure to meet your needs and exceed your expectations.

Trust Volsun for all your thermal management needs and experience the difference that quality and performance can make. Upgrade your electronic projects with Volsun’s 3.0w/mk Thermal Potting Compound today and ensure that your devices run cool, efficient, and reliable for years to come

Item |

Typical Data |

Test Method |

Mixing ratio |

1:1 |

/ |

Color - After mixing |

Grey |

Visual |

Viscosity (Component A) @25℃ |

7000-9000cps |

ASTM D2196 |

Viscosity (Component B) @25℃ |

7000-9000cps |

ASTM D2196 |

Viscosity (After mixing) @25℃ |

7000-9000cps |

ASTM D2196 |

Opening hours @25℃ |

≥60min |

/ |

Curing condition |

30min/50℃;20min/100℃ |

/ |

Thermal Conductivity |

2.0±0.2 W/m·k |

ASTM D5470 |

Hardness |

45±5 Shore A |

GB/T 531.1-2008 |

Density |

2.8±0.2 g/cm3 |

GB/T 1033.1-2008 |

Tensile strength |

>0.2MPa |

GB/T 528-2009 |

Elongation at break |

>10% |

GB/T 528-2009 |

Flame retardance |

V-0 |

UL94 |

Breakdown strength |

≥10 kV/mm |

GB/T 1695-2005 |

Volume resistivity |

≥ 1.0×1013 Ω·cm |

GB/T 1692-2008 |

Size |

Package |

VS-TP2001 - 1kg |

Component A: 0.5kg; Component B: 0.5kg |

VS-TP2001 - 20kg |

Component A: 10kg; Component B: 10kg |

VS-TP2001 - 40kg |

Component A: 20kg; Component B: 20kg |

VS-TP2001 - 80kg |

Component A: 40kg; Component B: 40kg |

VS-TP2001 0 100kg |

Component A: 50kg; Component B: 50kg |

Copyright © Suzhou Volsun Electronics Technology Co., Ltd All Rights Reserved.