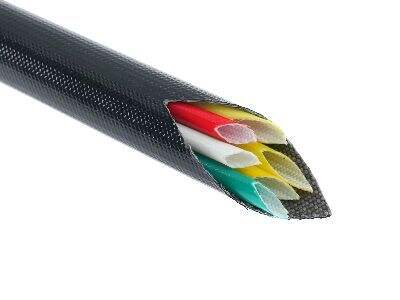

It is used in various places, such as electronic work and industries. Fiberglass sleeves They are designed to shield wires and other materials from heat, moisture and wear. Standard vs. High-Temperature Fiberglass Sleeves There are two primary types of fiberglass sleeves. We produce both at Volsun to cater for different requirements. Knowing the distinctions between them can help you decide which is best for your project. Let’s take a look at what makes standard and high-temperature fiberglass sleeves different, and why you may actually prefer to choose the high temperature option for your application

What are Standard vs High Temp Fiberglass Sleeves

Regular fiberglass sleeves can withstand some heat, but only up to a point. They are frequently used in locations where the temperature doesn’t rise too much. And so these are suitable for a lot of standard uses. But if you push them too hard, they might not work properly. High heat Fiberglass sleeves, meanwhile, are designed for use in even hotter conditions. They can withstand searing heat without fouling. That makes them better for jobs in industries such as automotive, aerospace or anywhere that generates a lot of heat. The materials and how they are treated are the main differences. High-temperature sleeves last longer in harsh environments than standard sleeves. You’ll also want to consider thickness. High-temperature sleeves are usually thicker, providing more protection. So if you are working with something that gets really hot, high-temperature fiberglass sleeves from Volsun are the ones to pick

Advantages of Using High Temperature Fiberglass Sleeves Instead of Conventional Sleeve Types

Opting for High-Temperature Fiberglass Sleeves There are numerous reasons to consider high temperature fiberglass sleeves. For one, they are better at blocking heat. The implication of this is that it’s less likely for wires or components that are encased in these to get damaged. In industries where safety is most important, high-temperature sleeves can help prevent accidents. Plus, these sleeves can last a long time. They do not stretch as easily and because the resist heat better, they won’t wear out as quickly. That can save money over time because you won’t need to replace them as frequently. High-temperature sleeves also have other advantages. They can fight off chemicals, so they work for areas like factories where chemical use is common. Which means they are splash-proof and can keep your gear safe from spills. Another good thing about the high-temperature sleeve is their flexibility. They are stiff yet flexible and can be manipulated/bent by hand. It’s easy to install them; even if you’re cramped for space. At Volsun, we think that knowing the good stuff can help you make more informed decisions and work with safer materials. The ideal fiberglass sleeve, standard or high temperature gloss, can ensure your satisfaction for a job well done

Which Industries Benefit the Most from High-Temperature Fiberglass Sleeves

High-temperature fiberglass sleeves are extremely effective in a wide variety of markets. These sleeves are manufactured from specialized materials which have some very impressive heat resistant properties. Automotive is one of the largest sectors employing these sleeves. Cars and trucks have a variety of parts that may become hot, especially near the engine. By insulating wires and other components in high-temperature fiberglass sleeve you can make them work better and last longer. "It's important, particularly for racing car applications where performance is so critical and failure can be costly

The aerospace industry also benefits greatly from it. You need to have a safe, reliable airplane. High temperature Fiberglass Sleeves are used to protect wires and cables from temperatures up to 1200°F during flight. This helps guard against electrical issues that might occur if the wires become too hot. Safety is the first thing when aviation is in question, and with these sleeves, you can be sure that everything works as it should

High-temperature fiberglass Braiding is also utilized by the electrical industry. There’s a whole lot of heat in places where electricity is generated or sent across the grid. These sleeves correctly guard wires and cable against heat damage, electricity flows safely and effectively. This is critical for power plants and factories, where machines are continuously operating

Finally, the field of manufacturing has its uses for high temperature fiberglass sleeves. Factories and machinery can generate a lot of heat when they are running. Utilizing these sleeves on all your parts helps to keep everything cool and in check. That could mean less downtime for repairs, which is good for its business. In general, high temperature fiberglass sleeves have been very beneficial in a number of industries and situations where heat is an issue. Companies such as Volsun manufacture these sleeves to suit the needs of many different types of businesses, keeping them up and running while allowing their employees to work safely

How to Pick the Right Fiberglass Sleeve for Your Application

It can be difficult to find the perfect fiberglass sleeve for your requirements, however it’s essential in order that you do. The first thing to consider is the temperature. High-temperature fiberglass sleeves can withstand far higher heat than conventional sleeves. If you already know the highest temperature at which the material will be exposed, it’s best to select a sleeve that has an even higher heat resistance. This will provide you with an additional layer of protection while allowing the sleeve to have a long life

Think about the size of the sleeve next. You must measure the wires or cables to cover. So it all fits snug on the wire without being to much. Too much flex, and it probably won’t offer the protection you need. If too tight, it could damage the wire or be difficult to install. Getting the size right is critical to making sure nothing gets in the way

Also, a significant determinant is the environment in which the sleeve will be applied. If it’s going to be in a location that has chemicals, moisture or other extreme conditions you need to ensure the fiberglass sleeve is made for those elements. Some are chemical-resistant, while others can work better with wet surfaces. If you know what sort of environment your sleeve will be exposed to, it can inform the best choice for you

Last, consider the requirements of your project. For instance, if you work in an industry such as aerospace or automotive, you may require a sleeve that complies with certain safety standards. " - Learn about these standards so you can be sure the fiberglass sleeve you select meets them. You will get couple of options in terms of companies which can serve you with suitability, firms like Volsun there to help you out. Taking the above factors into careful consideration would let you pick the best fiberglass sleeve to protect your wires and cables from harm

Where to Look for Dependable Providers of High Temperature Fiberglass Sleeves

And finding a reliable provider of high temperature fiberglass sleeves is critical to receive excellent products. (One of the best places to begin that talent search is at their Facebook page.) Most companies maintain websites, where you can look through their wares and read about their features. When choosing a supplier, be sure to review their reviews and ratings. This can help give you a sense of what kind of product quality they provide and how well they treat their customers. Good reviews are usually an indication that the supplier is dependable

A second method to locate suppliers is through soliciting recommendations. If you know others in industries that use high-temperature fiberglass sleeves, inquire about where they purchase their materials. They might have some helpful tips and they can lead you to the best suppliers. Contact with other professionals within your industry can also result in you finding new suppliers that you had not previously been aware of

Trade shows and industry events provide great opportunities for connecting with suppliers in person. At these shows, you can look at the products and ask suppliers direct questions. Doing so can help you learn differences among products, and find the best one to fit your needs. It’s a wonderful opportunity for networking and making connections in your industry, too

And, last but not least is Volsun, the supplier of quality products such as high temperature fiberglass sleeve. They are well respected and offer a variety of options to accommodate various specifications. When shopping around for a supplier, seek out those who deal specifically with high-temperature materials as they’ll know what you’re talking about! By researching and choosing a trustworthy supplier you will have peace of mind knowing you’ve received the highest quality products for your project needs

Table of Contents

- What are Standard vs High Temp Fiberglass Sleeves

- Advantages of Using High Temperature Fiberglass Sleeves Instead of Conventional Sleeve Types

- Which Industries Benefit the Most from High-Temperature Fiberglass Sleeves

- How to Pick the Right Fiberglass Sleeve for Your Application

- Where to Look for Dependable Providers of High Temperature Fiberglass Sleeves