A Case Of Reliable Insulation Solutions for High-Performance Power Infrastructure

In the demanding energy landscape of the Middle East, where extreme temperatures and industrial growth converge, the reliability of power distribution equipment is non-negotiable. For over a decade, our company has been a strategic partner to one of the region’s premier electrical manufacturers. Based in Saudi Arabia, this industry leader specializes in high-quality oil and dry-type distribution transformers, as well as low-voltage switchgear solutions.

To maintain their "Power to Life" philosophy, they require components that meet rigorous international standards (ISO/IEC). Our Busbar Heat Shrink Tubing has become a critical part of their manufacturing process, ensuring long-term insulation and safety.

The client faces two primary challenges:

1. Environmental Stress: Operating in regions with high ambient temperatures and desert dust requires insulation that doesn't degrade or crack over time.

2. Space Optimization: As modern switchgear and substations become more compact, the air clearance between copper busbars is reduced. This increases the risk of flashovers or accidental short circuits caused by wildlife or dust accumulation.

Volsun’s Solution: Premium Busbar Heat Shrink Tubing

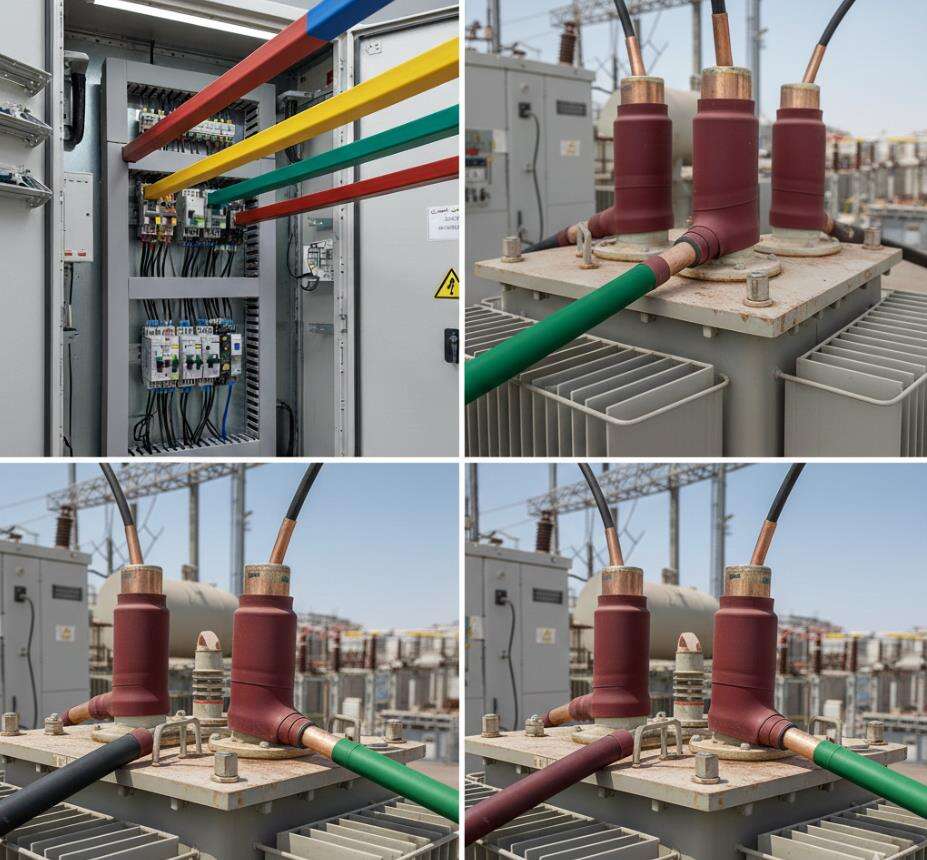

Working closely with their engineering team, we provided specialized polyolefin heat-shrinkable sleeves tailored for their transformer bushing connections and switchgear busbar systems.

● Superior Dielectric Strength: Our tubing provides high-voltage insulation (up to 35kV), allowing engineers to reduce the spacing between busbars without compromising safety.

● Thermal Stability: Designed to withstand continuous operating temperatures from -55°C to 125°C, the material remains flexible and robust even in the harsh Middle Eastern climate.

● Flame Retardancy & Anti-Tracking: The halogen-free, flame-retardant properties ensure that in the rare event of a fault, the insulation does not contribute to fire spread or release toxic gases.

Real-World Application in Transformers & Switchgear

In their production facility in Dammam, our heat shrink tubing is applied to both rectangular and round busbars. By "shrink-wrapping" intricate shapes with a simple heat application, the client achieves a uniform, protective layer that seals out moisture and contaminants.

For their oil-immersed transformers, our heat shrink tubing protects leads and connections, and based on test data, our busbar heat shrink tubing ensures the internal electrical integrity remains unchanged for a lifespan of over 25 years.In their LV/MV switchgear panels, the color-coded sleeves (Red, Yellow, Blue) not only provide insulation but also simplify phase identification for maintenance crews.

Why Partners Choose Our Insulation Solutions?

The longevity of this partnership is built on more than just a product; it’s about consistency. Our client values our commitment to:

● Compliance: Meeting RoHS standards required for large-scale utility projects.

● Efficiency: Reducing installation time compared to traditional taping methods.

● Safety: Minimizing the "arc flash" risk, which is a top priority for utility providers and industrial plants across the GCC.

In short, thousands of transformers and switchgear units powered by our insulation solutions are operating across the Middle East’s electrical grid. By integrating our busbar heat shrink tubing, this leading manufacturer continues to deliver reliable energy solutions that drive regional development.

As the global demand for sustainable and safe power distribution grows, we remain dedicated to providing the high-performance insulation materials that make "Power for Life" a reality.